The construction industry is on the cusp of a profound transformation, moving rapidly beyond traditional methods and even the widespread adoption of Building Information Modeling (BIM). While BIM has undoubtedly revolutionized project coordination and visualization, the true “next generation of next-gen construction technology” is pushing boundaries further, integrating advanced concepts like artificial intelligence, robotics, IoT, and digital twins to create a truly connected, intelligent, and efficient built environment. This era of profound change promises to address long-standing challenges in productivity, safety, and sustainability, charting a course for a more innovative future in construction.

The Foundation: How BIM Paved the Way for Next-Gen Construction Technology

Building Information Modeling (BIM) laid crucial groundwork for the advancements we see today. By creating a collaborative 3D model with embedded data, BIM significantly improved communication, reduced errors, and streamlined workflows. It became the central hub for project information, enabling better design, analysis, and facility management. The importance of BIM in fostering digital collaboration is clear, setting the stage for even more integrated and intelligent systems. For those looking to enter this evolving field, BIM training is clearly the smart gateway to a future-ready AEC career. Without the digital backbone and data-centric approach introduced by BIM, the seamless integration of the truly

The Rise of AI and Machine Learning in Next-Gen Construction Technology

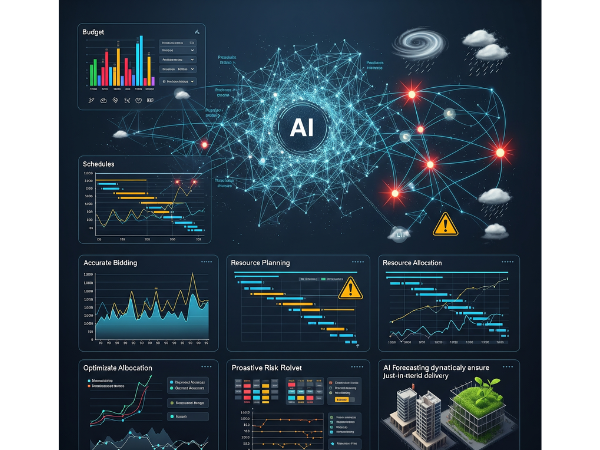

Artificial Intelligence (AI) and Machine Learning (ML) are at the forefront of the next-gen construction technology revolution, offering capabilities far beyond static modeling. Their ability to analyze vast datasets, learn from patterns, and make predictions is fundamentally reshaping how projects are managed and executed.

1. Predictive Analytics and Project Optimization: AI algorithms can sift through historical project data including budgets, schedules, resource allocation, and even weather patterns to identify potential risks and bottlenecks before they emerge. This predictive power allows for more accurate bidding, optimized resource planning, and proactive risk mitigation. For instance, AI can forecast material demand, ensuring just-in-time delivery and minimizing waste, directly contributing to more sustainable structures. It’s a leap from reactive problem-solving to proactive prevention.

2. Generative Design and Material Efficiency: AI-powered generative design tools can rapidly explore thousands, if not millions, of design permutations based on specified parameters like structural integrity, material cost, energy efficiency, and even aesthetic preferences. This not only accelerates the design process but also uncovers innovative solutions that human designers might miss. By optimizing material quantities and minimizing off-cuts, AI significantly contributes to waste reduction and lessens the environmental footprint of projects. The impact of material selection on structural integrity, which can be optimized by AI, is a critical consideration in modern construction.

3. Enhanced Scheduling and Progress Monitoring: Advanced AI models are transforming project scheduling. They can create dynamic schedules that adapt in real-time to changing site conditions, material delays, or unforeseen challenges. Utilizing data from drones, IoT sensors, and wearable devices, AI systems continuously track progress, instantly flagging deviations from the plan. This continuous monitoring allows project managers to make informed decisions and intervene promptly, keeping complex projects, like high-rise buildings, on track and within budget.

Robotics and Automation: The Hands of Next-Gen Construction Technology

While AI provides the brains, robotics provides the brawn and precision. The integration of robotics in construction is automating dangerous, repetitive, and labor-intensive tasks, thereby enhancing safety and accelerating project timelines.

1. Autonomous Construction Equipment: Self-driving excavators, bulldozers, and dump trucks are becoming increasingly common on large-scale construction sites. These autonomous machines can operate tirelessly in hazardous conditions, such as unstable terrain or areas with falling debris, removing human workers from harm’s way. This automation not only boosts productivity but also ensures a consistent quality of work.

2. Robotic Fabrication and Assembly: Off-site prefabrication is gaining traction, and robots are central to this trend. Robotic arms can precisely cut, weld, and assemble building components, such as rebar cages or wall panels, in a controlled factory environment. This level of precision reduces material waste and improves the overall quality and consistency of prefabricated elements. The benefits of pre-engineered buildings for commercial projects are further amplified by robotic fabrication.

3. On-Site Robotics for Specific Tasks: From bricklaying robots that can lay bricks faster and more accurately than human masons, to concrete pouring robots and even robots designed for rebar tying, specialized robots are emerging to tackle specific on-site tasks. These machines augment human capabilities, allowing skilled workers to focus on more complex, value-added activities. Demolition robots can also handle dangerous tasks, improving safety and efficiency on the job site.

The Connected Job Site: IoT and Digital Twins as Next-Gen Construction Technology

The Internet of Things (IoT) and Digital Twins are essential components of the next-gen construction technology ecosystem, creating a hyper-connected and data-rich environment.

1. IoT Sensors for Real-time Data: IoT sensors deployed across construction sites can monitor everything from equipment performance and structural integrity to environmental conditions like temperature and humidity. These sensors provide real-time data streams that feed into AI analytics, enabling proactive maintenance, immediate identification of issues, and optimized operational efficiency. For instance, sensors can alert managers to potential structural problems, signaling when a building might need a structural inspection.

2. Digital Twins for Lifecycle Management: A digital twin is a virtual replica of a physical asset, continuously updated with real-time data from IoT sensors and other sources. In construction, a digital twin can represent an entire building or even a city, from its initial design through construction, operation, and maintenance. This live, dynamic model allows stakeholders to monitor performance, simulate scenarios, predict maintenance needs, and optimize operations throughout the building’s entire lifecycle. This continuous feedback loop drives informed decision-making and fosters long-term sustainability.

Augmented and Virtual Reality: Immersive Next-Gen Construction Technology

Augmented Reality (AR) and Virtual Reality (VR) are transforming how construction professionals interact with designs and job sites, offering immersive and intuitive experiences.

1. Immersive Design Reviews: VR allows architects and engineers to walk through a proposed building design in a fully immersive 3D environment, identifying clashes, visualizing spatial relationships, and gaining a better understanding of the user experience before any physical construction begins. This significantly reduces costly reworks.

2. On-Site Visualization and Training: AR overlays digital information onto the real-world environment. On a construction site, workers can use AR-enabled devices (like smart glasses) to view BIM models superimposed on the physical structure, guiding them through installation procedures, identifying hidden utilities, or checking for design deviations. AR can also provide interactive training for new equipment or complex tasks, enhancing worker skill and safety.

Addressing Challenges and Looking Ahead: The Future of Next-Gen Construction Technology

While the promise of next-gen construction technology is immense, its widespread adoption faces several challenges. The initial investment costs for advanced AI systems and robotics can be substantial. There’s also a pressing need for upskilling the workforce to operate, maintain, and leverage these new tools effectively. Data interoperability between different platforms and robust cybersecurity measures are also critical concerns.

However, the industry is rapidly adapting. Governments and private organizations are investing heavily in research and development, and educational institutions are updating curricula to prepare the next generation of construction professionals. The future of the structural engineering role, for instance, will evolve to incorporate these technologies.

The trajectory points towards a future where:

- Integrated Digital Platforms: All aspects of a construction project, from design and planning to execution and maintenance, will be seamlessly managed on unified digital platforms.

- Human-Robot Collaboration: Instead of replacement, we will see enhanced collaboration between human workers and intelligent machines, leveraging the strengths of both.

- Data-Driven Decision Making: Every decision, from material procurement to risk management, will be informed by real-time data analytics and AI-driven insights.

- Increased Resilience and Sustainability: Construction projects will be inherently more resilient to external factors, including climate change, and designed with a minimal environmental footprint through optimized processes and smart building technologies.

The shift towards next-gen construction technology is not just about adopting new tools; it’s about fundamentally rethinking processes, fostering collaboration, and building a more efficient, safer, and sustainable future for the built world. The journey beyond BIM is well underway, and it promises to transform the construction industry into a high-tech, data-driven powerhouse.

FAQ’s:-

Q1: What is the primary difference between BIM and next-gen construction technology?

A1: While BIM provides a foundational digital model for collaboration, next-gen construction technology integrates advanced capabilities like AI for predictive analytics, robotics for automation, IoT for real-time data, and digital twins for comprehensive lifecycle management, moving beyond static modeling to intelligent, dynamic systems.

Q2: How does AI contribute to sustainability in construction?

A2: AI contributes to sustainability by optimizing material usage and reducing waste through precise design and robotic fabrication, enhancing energy efficiency in buildings through smart management systems, and lowering carbon emissions by optimizing logistics and machinery efficiency.

Q3: What role do robots play on a construction site?

A3: Robots automate dangerous, repetitive, and labor-intensive tasks, improving safety by removing human workers from hazardous environments. They are used for autonomous equipment operation, precise off-site fabrication, and specific on-site tasks like bricklaying and demolition.

Q4: What are Digital Twins in the context of construction?

A4: A digital twin is a virtual replica of a physical building or asset that is continuously updated with real-time data from IoT sensors. It allows for monitoring performance, simulating scenarios, predicting maintenance needs, and optimizing operations throughout the asset’s entire lifecycle.

Q5: What challenges are faced in adopting next-gen construction technology?

A5: Challenges include high initial investment costs, the need for a skilled workforce to operate and maintain new technologies, ensuring data interoperability, and addressing cybersecurity concerns.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.