Building Information Modeling (BIM) has revolutionized the Architecture, Engineering, and Construction (AEC) industry, moving us from flat drawings to intelligent, 3D models. But the story doesn’t end when the construction dust settles. In fact, that’s where the real, long-term value of BIM specifically 6D BIM truly shines. The “D’s” in BIM represent dimensions of data, and 6D adds the critical layer of Facility Maintenance and lifecycle management information to the model.

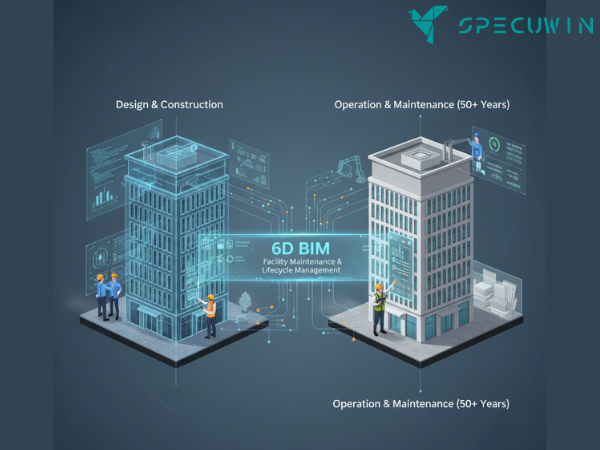

Think of a building’s lifecycle: design and construction might last a few years, but its operation and maintenance phase can span 50 years or more. Historically, when a project was completed, facility managers would inherit a mountain of paper manuals, disconnected warranties, and as-built drawings that were often outdated. This information gap made proactive, cost-effective Facility Maintenance a frustrating, reactive nightmare.

6D BIM changes that. It’s the digital bridge that connects the vast data created during the project phase to the people who manage the building daily, fundamentally improving Facility Maintenance and operations.

Understanding the Dimensions of BIM:-

Before diving into 6D, it helps to briefly understand the progression:

- 3D BIM: The geometric model (width, height, depth).

- 4D BIM: Time/scheduling data (integrating the model with the construction schedule).

- 5D BIM: Cost/estimating data (connecting model elements to budget).

- 6D BIM: Facility Maintenance & Lifecycle Management data. This includes details like manufacturer specifications, installation dates, warranty information, and maintenance schedules everything a facility manager needs to run the building efficiently.

- (7D BIM): Sustainability and deconstruction information.

For the facility manager, 6D BIM is the ultimate digital asset, making their job not just easier, but smarter.

The Problem with Traditional Facility Maintenance:-

In the traditional handover process, crucial information gets lost in translation. When a chiller breaks down, the facility team often has to:

- Search through dusty archives for the original purchase order or manual.

- Guess the last time it was serviced.

- Manually contact the supplier to check the warranty status.

- Decide whether to repair or replace, often with incomplete cost data.

This reactive approach is expensive, inefficient, and leads to greater downtime. This is why having a proactive strategy is so important, and why understanding the link between the design process and the long-term management of assets is key.

Five Ways 6D BIM Revolutionizes Facility Maintenance:-

6D BIM transforms the entire post-construction phase by making data instantly accessible, actionable, and visual.

1. Instant Asset Information & Smarter Maintenance:

Every component in a 6D model is linked to a database. Need to find the specs for a specific air handler? Click on it in the model. The model instantly reveals its:

- Manufacturer and model number

- Date of installation and predicted lifespan

- Warranty end date

- Last service date and a log of past repairs

- Direct link to the operation manual and replacement part supplier

This instant access cuts down diagnostics time from hours to minutes, allowing for truly smarter maintenance.

2. Optimized Predictive and Preventive Maintenance:

Instead of fixing things after they break (reactive maintenance), 6D BIM facilitates preventive and predictive strategies. The model can be integrated with a Computerized Maintenance Management System (CMMS).

- Preventive: The system automatically flags when an asset is due for maintenance based on its manufacturer-recommended schedule or usage logs.

- Predictive: By integrating the model with Digital Twins (a concept explored in depth in a separate discussion), real-time sensor data (like temperature, vibration, or energy consumption) can be monitored against the model’s design parameters. Anomalies trigger alerts before a catastrophic failure occurs. This seamless integration of real-time data is critical for enhancing operations.

Read more on:- The revolutionary impact of digital twins on facility management and operations

3. Streamlined Space and Asset Management:

Facility managers are constantly juggling space, from reconfiguring offices to tracking movable assets. The 6D model serves as a single source of truth for all spatial and asset data.

- Need to reconfigure a floor? Simulate the change in the 3D model to assess spatial conflicts or impacts on HVAC/lighting systems before moving a single desk.

- Tracking the location and condition of key furniture or equipment becomes effortless, allowing for better utilization and inventory management.

4. Cost Forecasting and Energy Efficiency (The Ultimate Savings):

The financial savings over a building’s life are arguably the biggest benefit. By linking maintenance needs to cost data, 6D BIM enables:

- Accurate Life-Cycle Costing: Facility managers can see the projected cost of ownership (maintenance, replacement, energy) for every asset. This allows them to budget more accurately and make better decisions on when to repair or replace equipment.

- Energy Optimization: Since the model contains thermal and energy performance data, integrating it with real-time utility meters helps identify energy waste immediately. For example, if a specific zone’s HVAC unit is using more power than the model predicts, it flags a potential efficiency issue or a hidden maintenance need. Understanding innovations in sustainable structures can also tie into these efficiency gains.

Read more on:- Sustainable Structures: Eco-friendly approaches in modern construction

5. Better Disaster Preparedness and Training:

A comprehensive 6D model can be used as a powerful training tool and a critical resource during emergencies.

- Training: New staff can virtually navigate the facility to locate critical systems (valves, shut-offs, fire panels) long before they need to find them under pressure.

- Emergency Response: In an emergency, first responders can access a simplified version of the model to quickly identify escape routes, structural weak points, and the location of hazardous materials.

Connecting the Dots: 6D BIM and the Future of AEC Careers:-

The demand for professionals who can manage this wealth of information is growing. Your guide to becoming an outstanding BIM Specialist emphasizes the increasing value of these skills. The transition from traditional CAD workflows to comprehensive BIM is essential for enhanced project delivery. As technology continues to evolve, the integration of BIM with other cutting-edge concepts like AI and Robotics (further discussed in “How AI and Robotics are Revolutionizing Construction“) and the broader implications of technology in structural analysis and design will only deepen the impact of 6D on Facility Maintenance. This convergence positions professionals with BIM knowledge at the forefront of a future-ready career in AEC.

Conclusion:-

6D BIM shifts the paradigm from simply operating a building to intelligently managing it over its entire lifespan. By digitizing, centralizing, and linking all critical asset information, it ensures that facility teams are proactive, not reactive. The result is a building that is cheaper to run, more energy-efficient, safer, and provides a better experience for its occupants. Investing in 6D BIM isn’t an expense; it’s the smartest long-term decision for any building owner or facility manager looking to master the art of Facility Maintenance and maximize their asset’s value.

FAQ’s:-

1. What is the main difference between 5D and 6D BIM?

A. 5D BIM focuses on Cost and estimation during the design and construction phase, connecting the model elements to budgets and quantities. 6D BIM, on the other hand, is specifically focused on Facility Maintenance and operations information, attaching lifecycle data like manufacturer specs, warranty details, and maintenance schedules to the model after construction.

2. Is 6D BIM the same as a Digital Twin?

A. No, but they are closely related. 6D BIM is the detailed, static data model that contains all the asset information needed for maintenance. A Digital Twin is a dynamic, living virtual replica of the building that integrates the 6D model’s data with real-time sensor data from the physical building. A 6D model is often the foundational database for creating a functional Digital Twin.

3. What kind of information is stored in a 6D BIM model for Facility Maintenance?

A. A 6D BIM model stores non-geometric asset information crucial for operations. This typically includes the manufacturer’s name, product model number, installation date, expected lifespan, date the warranty expires, details on the required maintenance frequency, and links to operation and maintenance manuals.

4. What is the biggest financial benefit of using 6D BIM in operations?

A. The biggest financial benefit comes from a significant reduction in Life-Cycle Costs. By shifting from costly reactive repairs to cheaper, scheduled preventive and predictive maintenance, and by optimizing energy use based on accurate model data, organizations can save substantial amounts of money over the decades-long lifespan of the asset.

5. What software is required to utilize 6D BIM for Facility Maintenance?

A. While the 6D information is embedded in the native BIM software (like Revit), facility managers typically access and manage this data through specialized tools. These often include Computerized Maintenance Management Systems (CMMS) or Integrated Workplace Management Systems (IWMS), which are directly integrated with or pull data from the 6D BIM model.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.