In an era where construction speed, cost efficiency, and sustainable practices are no longer optional, the shift toward off-site construction methods is inevitable. At the heart of this revolution lies Pre-cast wall design. Think of traditional construction as tailoring a suit right on the customer slow, messy, and prone to weather delays. Pre-cast construction, on the other hand, is like manufacturing that suit in a controlled, high-tech factory: precise, fast, and repeatable.

A pre-cast wall is an element that is poured, cured, and finished in a dedicated factory or casting yard, then transported to the construction site and erected. This move from on-site to off-site is not just a logistical change; it’s a fundamental transformation of the entire Architectural, Engineering, and Construction (AEC) process. It’s about achieving a higher quality, stronger structure in a fraction of the time.

For architects, engineers, and developers alike, understanding the nuances of Pre-cast wall design is crucial for remaining competitive and delivering truly future-ready buildings. This isn’t just a trend; it’s a foundational skill for a future-ready career in AEC. So, let’s explore the revolutionary impact and technical considerations of these factory-made facades.

The Unmatched Benefits of Optimized Pre-cast Wall Design:-

The decision to choose pre-cast over traditional cast-in-place concrete offers a compelling list of advantages that address some of the biggest pain points in modern construction:

A. Accelerated Project Timelines:

One of the most significant benefits is speed. Because the walls are manufactured concurrently with site preparation and foundation work, the erection phase is dramatically faster. Imagine a structure where walls and floors are delivered like giant, ready-made LEGO blocks. This parallel process significantly cuts down the construction cycle, helping projects get to market sooner. In many cases, installation of a pre-cast wall can be completed in hours or days, saving weeks of traditional construction time.

B. Superior Quality and Consistency:

In a factory setting, every variable can be controlled: temperature, moisture, mix proportions, and curing time. This eliminates the uncertainty associated with on-site casting, which is exposed to unpredictable weather conditions. The result of precise, controlled manufacturing is a product with better density, higher strength, and a more consistent finish. This superior quality directly impacts the overall structural integrity of the building [The impact of material selection on structural integrity], a key concern for any structural engineering project.

C. Cost-Effectiveness and Waste Reduction:

While the initial unit cost of a pre-cast panel might seem higher than its cast-in-place counterpart, the overall project economics tell a different story. The speed of construction reduces labor costs and site overhead. Furthermore, factory production minimizes material waste, contributing to a more sustainable construction process. This efficiency gained is a testament to how Building Information Modeling (BIM) is transforming consultancy and design, and aligns perfectly with the principles of Green Building in India.

D. Enhanced Structural and Seismic Performance:

The quality control inherent in pre-cast manufacturing leads to walls with predictable and high-performance structural properties, making them inherently more resistant to fire, mold, and moisture than some traditional materials. Crucially, the connections between pre-cast elements can be engineered to be ductile and robust. This is vital for structures in seismic zones, as advanced Pre-cast wall design allows for complex joint detailing that can significantly improve the building’s ability to resist earthquake forces, connecting back to the importance of innovations in earthquake-resistant design.

Key Types and Applications in Pre-cast Wall Design:-

Pre-cast wall design is highly versatile, offering solutions for nearly every part of a building envelope and structure. The type selected depends entirely on the required function, from load-bearing to pure aesthetics:

- Solid Walls: These are the workhorses of pre-cast construction. They are typically load-bearing and designed to transfer gravity loads from the floors and roof down to the foundation, often doubling as shear walls to resist lateral forces. They are ideal for structures where robustness and fire separation are primary concerns.

- Insulated Sandwich Panels: These panels revolutionize energy efficiency. They feature a layer of continuous insulation (like rigid foam) sandwiched between two layers of concrete, or wythes, connected by non-conductive ties. This design provides remarkable thermal benefits, drastically reducing heating and cooling costs, and making them a key element of modern sustainable structures. By manufacturing the insulation layer in a controlled environment, these panels guarantee the required thermal resistance, a critical factor for achieving high energy ratings in new constructions.

- Architectural/Cladding Panels: When the wall’s primary role is aesthetic and protective, cladding panels are used. They are non-load-bearing and come with limitless possibilities for finishes, textures (replicating stone, brick, or wood), patterns, and colors. This allows architects to achieve stunning, complex façades with the durability and low maintenance of concrete.

- Retaining Walls and Boundary Walls: Pre-cast elements are frequently used for retaining soil or creating property boundaries quickly and affordably. The modular nature of these walls allows for rapid installation and long-term durability against weathering and soil pressure.

From Concept to Casting: The Role of BIM in Pre-cast Wall Design:-

The success of any pre-cast project hinges on meticulous planning, a step where technology truly shines. The industry is rapidly navigating the transition From CAD to BIM: navigating the transition for enhanced project delivery, making the Pre-cast wall design process faster and more accurate.

In a BIM environment, every pre-cast panel is modeled as a precise 3D object, incorporating all penetrations, connections, and lifting hardware. This level of detail is critical because, unlike cast-in-place concrete, core cutting or on-site modifications to hardened pre-cast panels are highly problematic and costly. The BIM model ensures all mechanical, electrical, and plumbing (MEP) services such as conduits and sleeves are coordinated and cast into the panel correctly at the factory. This proactive approach eliminates expensive clashes and rework, a common scourge of traditional construction.

The BIM model becomes the single source of truth for generating automated shop drawings, production schedules, and even logistics plans, reducing human error and accelerating the entire fabrication process. Furthermore, the digital twin capabilities derived from the BIM model can be passed on to facility managers, providing rich data for future maintenance and operations.

Structural Engineering Deep Dive: The Art of Pre-cast Wall Design Connections:-

For a structural engineer, Pre-cast wall design introduces unique and critical considerations that differ significantly from monolithic construction. The integrity of the final structure is entirely dependent on the quality of the connections, not the strength of the panel itself. A pre-cast panel is only as good as the system that ties it to the rest of the building.

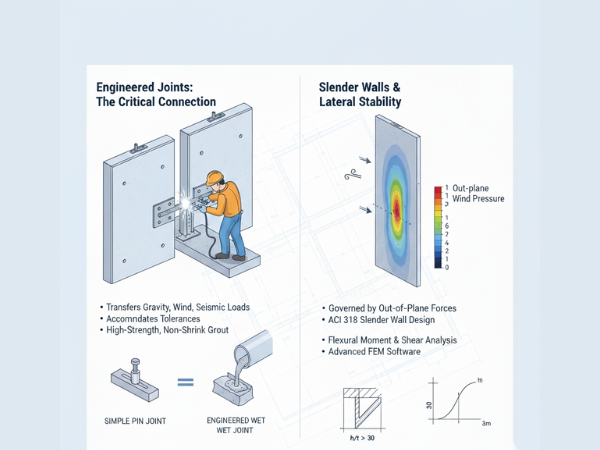

A. The Critical Role of Engineered Joints:

The joints between panels must be designed to transfer loads gravity, wind, and seismic forces effectively while accommodating construction tolerances. In seismically active regions, simple, slotted connections (which act as pin joints) are often insufficient as they don’t provide the necessary frame action for lateral stability. Instead, engineers must specify wet joints. These joints involve welding steel inserts embedded within the concrete panels together, and then enclosing the entire connection area with a high-strength, non-shrink grout.

B. Analyzing Slender Walls and Temporary Stresses

Many pre-cast walls, especially those used for non-load-bearing facades or boundary walls, fall into the category of slender walls. These walls are primarily governed by out-of-plane forces, such as wind pressure. Engineers utilize specialized design provisions, often based on codes like ACI 318, which employ the “Alternative Design Method for Slender Walls.” This robust analysis involves checking the wall’s capacity against flexural moment capacity and shear stress under these lateral loads, often using advanced analytical software based on the Finite Element Method (FEM) to accurately model complex geometry and load distribution.

Conclusion:-

Pre-cast wall design is more than just a convenient manufacturing process; it is a fundamental pillar of modern construction excellence. It embodies precision, speed, and long-term value, effectively shifting the burden of quality control from the unpredictable job site to the controlled environment of a factory.

For the modern AEC professional, embracing the collaborative, technology-driven process of pre-cast design is non-negotiable. By mastering the coordination challenges, understanding the nuances of connection detailing, and leveraging BIM for precision, we can build smarter, not harder, delivering projects that are ready for the demands of the 21st century and beyond. The future of construction is assembled, and Pre-cast wall design is our blueprint.

FAQ’s:-

1. Is pre-cast wall construction weaker than traditional cast-in-place concrete?

A. No. Due to factory-controlled conditions, pre-cast walls often achieve superior, more consistent quality, higher strength, and greater durability than on-site concrete. Their connections are specifically engineered for structural performance and seismic resistance.

2. How does Pre-cast wall design contribute to sustainable construction?

A. It reduces on-site material waste, allows for the integration of high-performance insulation (like in sandwich panels), and enables the use of recycled materials in the plant, aligning with sustainable structures and eco-friendly approaches.

3. Are there limitations to the architectural design when using pre-cast walls?

A. While there are module constraints, modern pre-casting allows for a wide range of finishes, textures, and even complex shapes. Generative design and advanced BIM processes have made it possible to incorporate highly creative and complex architectural elements using pre-cast units.

4. What is the role of BIM in Pre-cast wall design and fabrication?

A. BIM is essential. It allows for the precise 3D modeling of every panel, clash detection with other trades (MEP, structure), automated shop drawing generation, and the creation of digital data crucial for fabrication machines and site logistics.

5. Is Pre-cast construction suitable for high-rise buildings?

A. Absolutely. Pre-cast systems are widely used in high-rise construction, particularly for facades, structural walls, and floor slabs. They offer the necessary speed and quality control to meet the demanding schedules and stringent structural requirements of tall structures, similar to the challenges faced in the Structural engineering of high-rise buildings.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.