If you walk onto any major construction site today, you are likely witnessing a silent battle of titans. It’s not between the workers or the architects, but between the materials themselves. For decades, the Architecture, Engineering, and Construction (AEC) industry has been defined by two heavyweights: structural steel and reinforced concrete.

Choosing between them isn’t just about aesthetics; it’s a decision that impacts the budget, the timeline, the environmental footprint, and the longevity of the building. Whether you are a developer planning a commercial high-rise or a homeowner looking at a custom build, understanding the nuances of concrete versus steel is essential.

In this guide, we’re going to strip away the complex engineering jargon and look at the practical pros and cons. We will explore why concrete remains the go-to for some, while steel steals the show for others, helping you understand which material deserves to be the backbone of your next project.

The Titans of Construction: Steel and Reinforced Concrete Explained:-

Before we dive into the comparison, let’s establish what we are actually working with.

Reinforced concrete (often abbreviated as RC) is a composite material. Concrete is incredibly strong when compressed (pushed together) but relatively weak when pulled apart (tension). To fix this, we embed steel bars rebars inside the concrete. This marriage creates a material that can handle almost anything nature throws at it. It is the rock of the modern world.

On the other side, we have structural steel. This isn’t the metal you find in a soda can. We are talking about massive beams and columns made primarily of iron and carbon. It has one of the highest strength-to-weight ratios of any building material.

While these two are the standard, the industry is constantly evolving. To understand how these traditional giants stack up against newer innovations, you might want to read about Modern materials in structural engineering beyond concrete and steel.

Cost Dynamics: Is Concrete Cheaper than Steel?:-

This is usually the first question a client asks: “Which one is going to cost me less?” The answer, frustratingly, is: It depends.

Generally speaking, the raw material cost of concrete is lower than steel. Cement, aggregates, and water are readily available and relatively cheap. Steel, being a refined manufactured product, is subject to global market fluctuations. If there is a trade tariff or a supply chain issue, steel prices can skyrocket overnight.

However, raw material costs don’t tell the whole story. Reinforced concrete requires a lot of labor. You need crews to build formwork, tie the rebar, pour the mixture, and wait for it to cure. Time is money.

Steel, conversely, is prefabricated. The beams arrive on-site ready to be bolted or welded. This allows for a much faster erection process, which can save a fortune in labor costs and get the building generating revenue sooner. When analyzing your budget, you have to look at the “installed cost,” not just the material price.

For a deeper dive into how choices like this affect the safety and longevity of your investment, check out our guide on The impact of material selection on structural integrity.

Speed and Scheduling: Concrete Construction vs. Steel Erection:-

In the world of construction, speed is a massive factor. Here, steel often has the upper hand.

Because steel components are manufactured off-site in a controlled environment, site work can happen simultaneously. While the foundation is being poured, the steel columns are being fabricated. Once the foundation is ready, the steel goes up incredibly fast.

Reinforced concrete is a slower beast. It requires a sequential process: form, reinforce, pour, cure, repeat. You generally cannot start the next floor until the concrete below has reached a certain strength. Weather also plays a huge role; you can’t pour concrete in extreme rain or freezing temperatures without expensive precautions.

However, new technologies like precast concrete are narrowing this gap, allowing concrete walls and floors to be lifted into place much like steel.

Design Flexibility and Aesthetics in Concrete Structures:-

If your architect dreams of wild, sweeping curves, organic shapes, or heavy, brutalist aesthetics, reinforced concrete is the undisputed king.

Concrete starts as a liquid. This means it can be poured into almost any shape imaginable. It allows for a sculptural quality that linear steel beams struggle to replicate without expensive fabrication. Concrete also offers better noise insulation and dampens vibrations, which is why it is often preferred for residential apartment blocks and hospitals.

Steel offers a different kind of flexibility: open spaces. Because steel is so strong, you can span massive distances without needing columns in the middle of the room. This is why corporate offices and warehouses usually favor steel it allows for vast, open floor plans that can be reconfigured easily.

For really ambitious projects, engineers often use a mix. For example, look at the Burj Khalifa, which utilizes a high-performance reinforced concrete core to achieve its record-breaking height.

Sustainability: The Environmental Impact of Concrete and Steel:-

We cannot talk about modern construction without talking about the planet. Both materials have baggage here.

The production of cement (the key ingredient in concrete) is responsible for a significant chunk of global CO2 emissions. It is an energy-intensive chemical process. However, the industry is working hard on “green concrete” alternatives that use fly ash or slag to reduce the carbon footprint. Steel is energy-intensive to produce, but it has a superpower: recyclability. Steel is the most recycled material on earth. When a steel building is demolished, nearly 100% of that steel can be melted down and used again. Concrete, once cast, is much harder to recycle effectively, usually ending up as road base or landfill.

If you are aiming for a LEED certification or a net-zero building, the choice is complex. It often comes down to sourcing and lifecycle analysis. You can learn more about how the industry is shifting in our article on Sustainable structures and eco-friendly approaches in modern construction.

Durability and Fire Resistance in Concrete:-

When it comes to surviving a disaster, reinforced concrete has some distinct advantages.

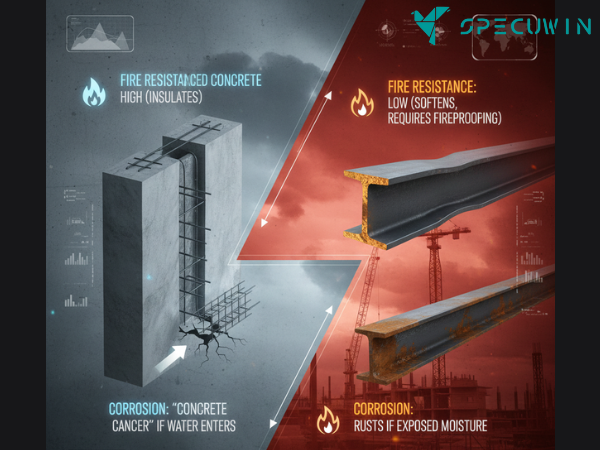

Concrete is inherently fire-resistant. It doesn’t burn, and it acts as an insulator, protecting the steel reinforcement inside from the heat. In a fire, a concrete structure maintains its integrity for a long time.

Steel, unfortunately, loses strength rapidly when exposed to high heat. It can soften and buckle, leading to catastrophic collapse. That is why structural steel must be covered in fireproofing materials (spray-on foam or board encasement), which adds to the cost and maintenance.

Regarding corrosion, both have weaknesses. Steel rusts if exposed to moisture. Reinforced concrete can also suffer from “concrete cancer” if water seeps in and rusts the rebar, causing the concrete to crack and spall. Proper maintenance is key for both. For those managing taller structures, understanding these risks is vital. Read more about the specific Structural engineering of high-rise buildings: challenges and solutions.

Conclusion: Making the Final Decision:-

So, who wins the battle of Steel vs. Reinforced Concrete?

There is no single champion. It comes down to the specific needs of your project.

- Choose Steel if: You need speed, have a tight urban site with no room for storage, need massive open spans, or are building a skyscraper where weight is a major concern.

- Choose Reinforced Concrete if: You need complex shapes, superior soundproofing, inherent fire resistance, or if material availability in your region favors cement over imported steel.

The best approach is to bring your structural engineer in early. They can run the numbers and help you find the sweet spot between vision, cost, and physics.

FAQ’s:-

1. Is reinforced concrete cheaper than steel for residential homes?

A. Generally, yes. For smaller residential projects, reinforced concrete or masonry is often more cost-effective because it relies on local materials and general labor. Steel fabrication usually requires specialized labor and heavy machinery (cranes) that can blow the budget on a small home.

2. Which material is better for earthquake resistance, steel or concrete?

A. Both can be excellent if designed correctly. Steel is naturally ductile, meaning it can bend without breaking, which is great for absorbing seismic energy. Reinforced concrete is heavy and rigid, but with proper detailing (ductile detailing), it can be made to withstand significant earthquakes.

3. Can I combine steel and concrete in the same building?

A. Absolutely. This is called “composite construction.” A common example is using a steel frame for the structure but pouring concrete over metal decking for the floors. This utilizes the tensile strength of steel and the compressive strength and stiffness of concrete.

4. Does concrete have a higher carbon footprint than steel?

A. In terms of initial production, cement manufacturing is a massive CO2 emitter. However, the calculation is complex. Steel requires high energy to produce but is highly recyclable. Concrete offers thermal mass benefits that can lower a building’s energy usage over its lifetime (heating and cooling).

5. How long does a reinforced concrete building last compared to steel?

A. Both can last over 100 years if maintained. However, concrete generally requires less maintenance regarding fireproofing and corrosion protection. Steel needs regular inspections to ensure the protective coatings (paint or fireproofing) remain intact to prevent rust.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.