Have you ever wondered how modern skyscrapers manage to have such thin floors while spanning massive distances between columns? Or how large parking structures handle the weight of hundreds of cars without a forest of support pillars blocking the way? The answer often lies in a specific engineering technique. It’s a lot like wrapping a rubber band tightly around a stack of books to hold them together by adding internal pressure, you make the whole unit stronger. In the construction world, we call this Post-Tensioning.

In this guide, we are going to break down exactly what this technology is, why it has become a favorite for structural engineers, and how it is reshaping the way we build.

What is Post-Tensioning?:-

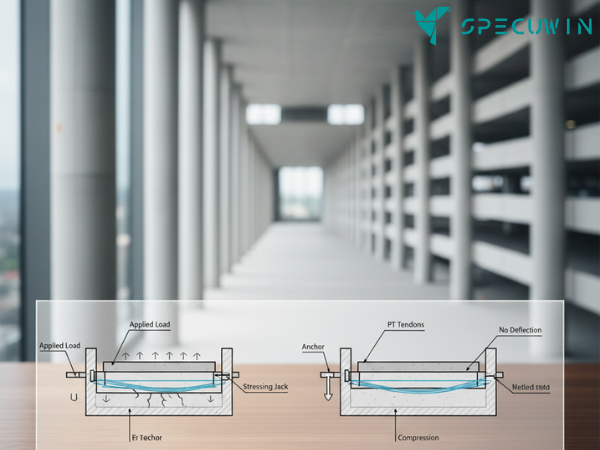

At its core, this concept is about active reinforcement. Traditional concrete is great at handling compression (being squashed), but it is terrible at handling tension (being pulled apart). When you put a heavy load on a slab, it wants to bend, causing the bottom to stretch and crack.

To counter this, engineers use high-strength steel strands, often referred to as tendons. Unlike standard rebar, which is passive and only starts working once the concrete cracks, these tendons are actively pulled tight. This squeezing force compresses the concrete before it ever bears a load, effectively preventing the tension that causes cracks. It is a proactive approach to structural strength rather than a reactive one.

The Mechanics Behind Post-Tensioning Systems:-

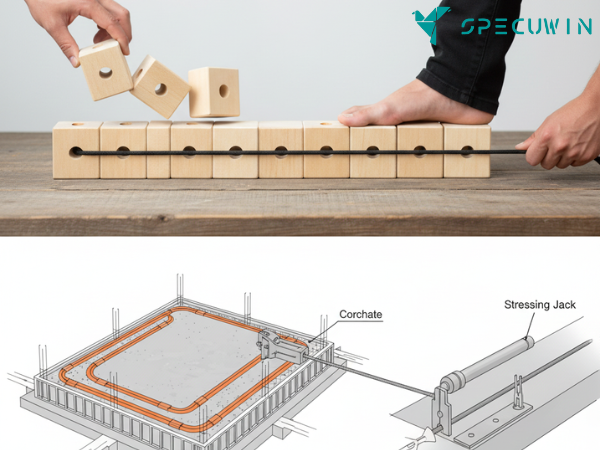

To understand how this works, imagine a row of wooden blocks with a hole drilled through the center. If you lift them, they fall apart. But if you run a rope through the holes and pull it tight from both ends, the blocks squeeze together and act as a solid beam. You can even stand on them.

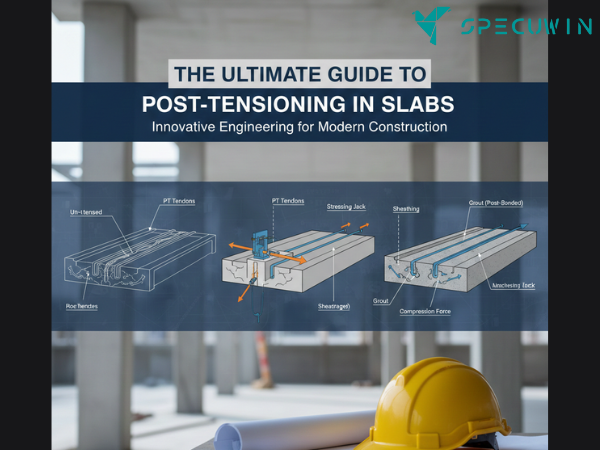

This implies a specific workflow on a job site. First, the steel tendons are laid out inside plastic or metal ducts within the formwork. Concrete is poured over them and allowed to cure until it reaches a specific strength. Once the concrete is hard, hydraulic jacks pull the steel strands to an incredible force, anchoring them at the edges of the slab.

This process significantly alters the internal forces of the structure. By introducing this internal compression, the slab can resist gravity loads much more effectively. This sophisticated interplay of forces relies heavily on choosing the right components. You can read more about how material choices define safety in our article on the Impact of material selection on structural integrity.

Why Choose Post-Tensioning for High-Rise Construction?:-

When developers plan a tall building, every inch of vertical space counts. This technique allows for significantly thinner slab depths compared to conventional reinforced concrete. A thinner floor means you save on concrete volume and weight.

When you reduce the weight of the floors, you reduce the load on the columns and the foundation. This creates a ripple effect of savings throughout the entire project. Furthermore, because the floors are thinner, developers can sometimes squeeze in an extra story within the same building height limit, maximizing the rentable area.

Additionally, this method allows for longer spans between columns. This open-concept flexibility is highly prized in commercial office spaces and residential high-rises where unobstructed views are a selling point. For a deeper dive into vertical construction challenges, check out our guide on Structural engineering of high-rise buildings .

Bonded vs. Unbonded Post-Tensioning:-

There are two primary ways to apply this technology, and the difference lies in how the steel interacts with the surrounding concrete.

1. Unbonded Systems In this variation, the steel strand is coated with grease and encased in a plastic sheathing. The steel moves freely inside this plastic tube. The force is transferred to the concrete only at the anchors on the ends of the slab. This is the most common method for residential and commercial slabs in North America because it is cost-effective and allows for rapid installation.

2. Bonded Systems Here, the strands are placed in a larger duct. After the steel is stressed, the duct is filled with a cementitious grout. This “bonds” the steel to the concrete along the entire length of the tendon. If a tendon were to be cut accidentally later, the remaining sections would still hold tension because of this bond. This method is often used in heavy civil works like bridges or transfer girders where durability and redundancy are critical.

Durability and Crack Control:-

One of the biggest headaches for any building owner is cracking. While concrete will almost always crack to some degree, this reinforcing method is exceptional at minimizing it. Because the slab is constantly being squeezed together, any small cracks that do form are held tight, often remaining invisible to the naked eye.

Fewer cracks mean fewer pathways for water and chemicals to seep in and corrode the steel. This makes the system ideal for parking garages or coastal structures exposed to harsh environments. However, maintenance is still key. If moisture does penetrate the anchors, corrosion can occur, which can be dangerous given the high energy stored in the cables. Regular checks are vital for these specialized systems. Learn what to look for in our post onTop 10 Structural Issues in Residential Buildings .

Cost Implications:-

Is it more expensive? The initial cost of the hardware (anchors, wedges, high-strength steel) and the specialized labor required to install and stress the tendons is higher than standard rebar. However, looking at the unit price tells the wrong story.

The savings come from the reduction in materials. You use less concrete and less total steel. The lighter structure means smaller foundations. The speed of construction is also faster; because the stressing creates an active load-bearing capacity early on, formwork can often be stripped and moved to the next floor sooner than with conventional reinforced concrete. When you view the total project budget, this method often emerges as the more economical choice for large-scale projects.

Conclusion:-

As we push for more sustainable construction, this technology plays a massive role. Using less material means a lower embodied carbon footprint for the building. Furthermore, advancements in composite materials are looking to replace steel tendons with carbon fiber or glass fiber, eliminating corrosion risks entirely.

Engineers are also using advanced software to model these complex forces with greater precision, ensuring that we are not over-engineering slabs but optimizing them for exactly the loads they need to carry.

FAQ’s:-

1. Is it safe to drill into a slab that uses this method?

A. Drilling or cutting into these slabs is risky. If you cut a tendon, it can snap with explosive force, popping out of the slab and causing severe injury or structural failure. You must use ground-penetrating radar (GPR) or X-rays to locate tendons before doing any renovation work.

2. Can this technique be used for residential homes?

A. Yes, it is frequently used for “slab-on-grade” foundations in areas with expansive soil (soil that swells when wet). The stiffness of the slab prevents it from cracking as the ground moves beneath it.

3. How long does the tension last?

A. The system is designed to last the life of the building. However, “creep” (the concrete shrinking slightly over time) and “relaxation” (the steel loosening slightly) do result in a small percentage of force loss, which engineers calculate and account for during the design phase.

4. What is the difference between this and Pre-tensioning?

A. Pre-tensioning is done at a factory. The steel is pulled tight before the concrete is poured (like in precast beams). Post-tensioning is done on the job site after the concrete has cured.

5. Does it make the floor soundproof?

A. Not necessarily. While the slab is denser, it is also thinner. Thinner slabs can sometimes transmit impact noise (footsteps) more easily than thick, heavy slabs. Soundproofing usually requires additional underlayment or ceiling treatments.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.