If you have ever walked past a construction site, you’ve probably seen the massive rotating drums of mixing trucks or piles of grey dust waiting to be transformed. To the untrained eye, concrete is just, well, concrete. It’s grey, it gets hard, and it holds things up.

But if you are planning a project whether it’s a simple backyard patio or a multi-story commercial complex treating all concrete as equal is a recipe for disaster. This is where Concrete Grades come into play.

Understanding the specific strength and composition of your materials is the difference between a structure that lasts a century and one that develops cracks within a year. In this guide, we are taking a deep dive into Concrete Grades to demystify the numbers, the mixes, and the applications that keep our built environment standing tall.

What Exactly Are Concrete Grades?:-

In simple terms, Concrete Grades act as a label that tells engineers and builders the compressive strength of the concrete mixture after it has cured for 28 days.

Think of it like the octane rating at a gas station. You wouldn’t put diesel in a high-performance sports car, and you wouldn’t put low-grade fuel in a heavy-duty truck. Similarly, in construction, the “grade” defines the quality and strength needed for a specific job.

The grade is usually denoted by the letter “M” (standing for Mix) followed by a number (e.g., M20, M30). This number represents the compressive strength in MegaPascals (MPa) or Newtons per square millimeter (N/mm²). For example, Concrete Grades labeled M25 have a compressive strength of 25 MPa.

Decoding the Mix: Ordinary vs. Standard vs. High Strength:-

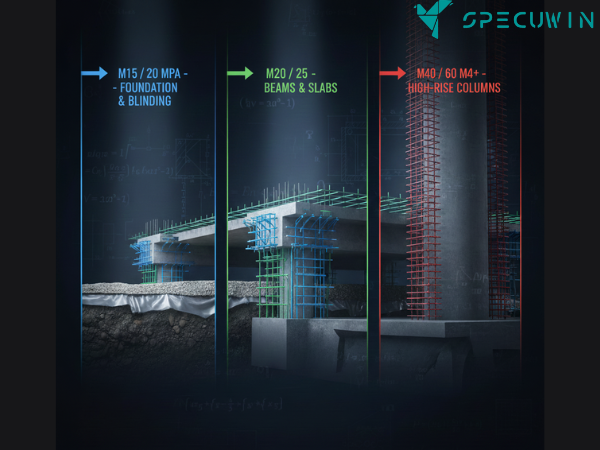

Not all mixtures are created equal. Concrete Grades are generally categorized into three main groups based on their strength and composition. The “recipe” usually involves a ratio of Cement : Sand : Aggregate.

1. Ordinary Concrete Grades (M5 to M20):

This category includes lower-strength mixes used for non-structural work.

- M5 & M7.5: These are very lean mixes, often used for footing under foundations or “mud mats” to provide a clean working surface. They aren’t meant to hold up a building.

- M10 & M15: Often used for leveling courses, bedding for footings, or simple flooring where heavy loads aren’t a concern.

- M20: This is the borderline entry into structural use. It is frequently used for domestic floor slabs, driveways, and sometimes internal walls.

2. Standard Concrete Grades (M25 to M45):

This is the “workhorse” category. If you are looking at a standard residential or commercial building, these Concrete Grades are likely doing the heavy lifting.

- M25 to M35: These are the most commonly specified grades for Reinforced Cement Concrete (RCC) construction. They are used in columns, beams, slabs, and footings. If you use a grade lower than this for critical load-bearing elements, you might run into significant problems later.

- M40 to M45: These are used in more demanding environments, such as chemical plants or structures exposed to aggressive weather, where durability and low permeability are required.

Read more about :- The Impact of Material Selection on Structural Integrity.

3. High-Strength Concrete Grades (M50 and Above):

When we start talking about skyscrapers, massive bridges, or structures that need to withstand extreme pressure, we enter the realm of high-strength concrete.

- M50 to M70: Used in high-rise buildings and long-span bridges.

- M80 and beyond: specialized mixes for ultra-high-performance projects (like the Burj Khalifa).

Why Selecting the Right Concrete Grades Matters:-

You might be tempted to think, “Why not just use the strongest concrete for everything?”

While that sounds safe, it is not economically viable or technically necessary. Using M60 grade concrete for a garden path is like buying a Ferrari to drive to the mailbox it’s overkill and a waste of money. Conversely, using M15 for a roof slab is dangerous.

Improper selection is often a leading cause of building failure. If you are unsure about the structural requirements of your specific project, it is vital to consult a professional.

Check out our guide on:- What is the Role of a Structural Engineer.

The Role of Water-Cement Ratio:

When discussing Concrete Grades, we cannot ignore the water-cement ratio. It is the single most critical factor affecting strength.

- Too much water: The concrete becomes easy to pour (workable), but as the excess water evaporates, it leaves behind tiny voids. These voids weaken the structure, effectively lowering the grade you thought you were getting.

- Too little water: The mix becomes harsh and difficult to place, leading to “honeycombing” (air pockets) which also compromises strength.

Concrete Grades and Modern Sustainability:-

The construction industry is under immense pressure to reduce its carbon footprint. Cement production is a massive contributor to CO2 emissions. Because higher Concrete Grades typically require higher cement content, engineers are constantly balancing the need for strength with the need for sustainability.

Modern engineering allows us to achieve high grades using supplementary cementitious materials like fly ash or slag, which reduces the environmental impact without sacrificing integrity. To learn more about eco-friendly building, read about Sustainable Structures: Eco-Friendly Approaches in Modern Construction.

The Future: Beyond Traditional Concrete Grades:-

While M20 and M25 are the standards today, the industry is evolving. We are seeing the rise of self-healing concrete, translucent concrete, and ultra-high-performance concrete (UHPC) that defies traditional grading limits.

As architects push the boundaries of design with complex curves and massive cantilevers, the materials must keep up. We are moving toward a future where “grade” isn’t just about compression strength, but also about flexibility and intelligence.

Curious about what’s next? Explore Modern Materials in Structural Engineering: Beyond Concrete and Steel.

Common Pitfalls to Avoid:-

When dealing with Concrete Grades, avoid these common mistakes:

- DIY Mixing for Structural Parts: It is very difficult to achieve a consistent M25 or M30 grade by mixing manually with a shovel. For structural elements, Ready Mix Concrete (RMC) is usually preferred to ensure consistency.

- Ignoring Curing: You can buy the most expensive Grade M40 concrete, but if you don’t cure it (keep it wet) for the required time, it might barely reach M20 strength.

- Overlooking Soil Conditions: The grade of your foundation concrete must account for the soil type. Aggressive soil chemicals can attack weak concrete.

Conclusion:-

Concrete Grades are more than just numbers on a blueprint; they are the assurance that your building will stand safe and sound for generations. Whether you are pouring a simple slab or designing a complex high-rise, respecting the science behind the mix is non-negotiable. Always ensure you are matching the grade to the application. When in doubt, don’t guess engineer it.

FAQ’s:-

1. What is the difference between M20 and M25 Concrete Grades?

A. The main difference is the compressive strength. M20 has a strength of 20 N/mm², while M25 has a strength of 25 N/mm². In practical terms, M20 is often used for domestic floors, while M25 is the minimum standard for reinforced concrete (RCC) structural elements like beams and columns.

2. Can I use a higher Concrete Grade than what is specified in the design?

A. Yes, using a higher grade (e.g., using M30 instead of M25) usually provides better strength and durability. However, it will be more expensive. You should not, however, use a lower grade than specified, as this compromises safety.

3. How do I know which Concrete Grades to use for my house foundation?

A. For a standard residential house, M25 is typically recommended for reinforced concrete foundations. However, if you are building on soft soil or a large structure, a structural engineer might specify M30 or higher.

4. Does the “M” in Concrete Grades stand for “Mix”?

A. Yes, the “M” stands for “Mix.” The number following it (e.g., 20, 30, 40) refers to the characteristic compressive strength of that mix in MPa (MegaPascals) after curing for 28 days.

5. How long does concrete take to reach its full grade strength?

A. Concrete does not reach full strength immediately. It typically gains about 65% of its strength in 7 days and reaches 99% of its “grade” strength (characteristic strength) after 28 days of proper curing.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.