The construction industry, long perceived as traditional, is undergoing a profound transformation. Historically, it relied on manual labor and heavy machinery. Now, it embraces a digital revolution. We have already seen the impact of Building Information Modeling (BIM) and digital twins. Yet, a new force is emerging: Construction Robotics. While 3D printing in construction has captured significant attention, the scope of robotics in building is far broader. It extends to the automation of diverse tasks. These range from precision bricklaying to autonomous site mapping.

For students of civil and structural engineering, understanding this shift is crucial. It’s about more than just futuristic machines. It represents a fundamental change in how projects are executed. Consequently, it redefines job roles, safety protocols, and productivity standards. This post will explore the evolution of construction automation. Furthermore, we will define what Construction Robotics entails. We will then examine its diverse applications beyond 3D printing. We will also discuss the benefits it offers and the challenges it faces. Finally, we will consider how aspiring engineers can prepare for this automated future.

I. Evolution of Automation in Construction: From Machines to Robots

Automation is not entirely new to construction. For decades, the industry has utilized powerful machines. Excavators, cranes, and bulldozers are prime examples. These machines automate tasks that are often too heavy or repetitive for humans. Prefabrication, moreover, also brought automation. Components are manufactured in controlled factory environments. This significantly speeds up on-site assembly.

However, Construction Robotics represents a new, higher level of automation. Traditional machines perform pre-programmed functions. Robots, conversely, exhibit a greater degree of intelligence and flexibility. They can sense their environment and process information. Then, they adapt their actions accordingly. This distinction is vital. It moves the industry from mere mechanization to intelligent automation. This shift allows robots to perform complex tasks. Indeed, they can even operate in dynamic, unstructured construction sites. Therefore, it marks a significant leap in productivity and safety.

II. Defining Construction Robotics

What exactly are Construction Robotics? Broadly speaking, they are autonomous or semi-autonomous machines. These machines are designed to perform specific tasks within the construction process. They utilize a combination of sensors, actuators, computational power, and sophisticated algorithms.

Key characteristics that define these robots include:

- Sensing Capabilities: Robots perceive their environment. This happens through various means, such as cameras, LiDAR, and GPS. They can thus understand their surroundings and current conditions.

- Intelligent Processing: Onboard computers process sensory data. They interpret instructions from digital models like BIM. Consequently, they make real-time decisions, adapting their actions.

- Precise Actuation: They execute physical tasks. This involves using robotic arms, grippers, wheels, tracks, or even aerial propulsion systems. Their movements are often highly precise.

- Adaptability: Many construction robots can adapt to changing site conditions. For example, they handle variations in material or unexpected obstacles. This makes them far more versatile than traditional, fixed automation systems.

These capabilities allow construction robots to undertake tasks with precision, speed, and consistency. They can also work effectively in environments that are dangerous or difficult for human workers.

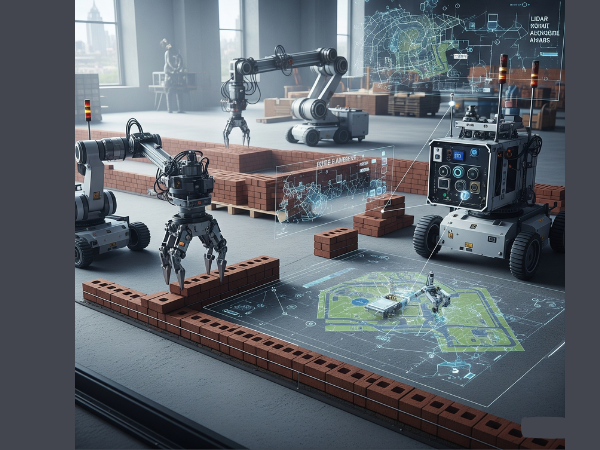

III. Diverse Applications of Construction Robotics (Beyond 3D Printing)

While 3D printing of concrete structures or components is a prominent robotic application, the field of Construction Robotics encompasses a much broader spectrum of uses. Its impact is visible across various phases of construction.

A. Robotic Fabrication & Assembly:

Robots excel at assembling modular components. This often occurs in controlled factory environments. Walls, floor sections, or entire volumetric units can be assembled with high precision and quality control. Furthermore, robots can weld, fasten, and connect intricate components. This is especially true for complex geometries found in structures like parametrically designed facades or long-span trusses.

B. On-Site Automation:

This is where the real transformation happens. Robotics are brought directly to the construction site.

- Robotic Bricklaying/Masonry: Automated bricklaying robots can lay bricks faster and more accurately than human masons. They follow digital plans precisely, ensuring both structural integrity and aesthetic consistency.

- Robotic Welding and Rebar Tying: Robots perform repetitive and labor-intensive tasks like welding steel structures or tying rebar cages. This improves speed, enhances quality, and significantly reduces worker fatigue.

- Automated Excavation and Demolition: Autonomous excavators can follow pre-programmed paths for digging. Similarly, demolition robots can safely dismantle structures in hazardous environments. They protect human workers from dangerous conditions.

- Surface Finishing Robots: Robots are being developed for tasks such as painting, plastering, and drywall installation. They ensure uniform application and consequently reduce labor needs and material waste.

C. Inspection & Monitoring:

Drones and mobile robots are revolutionizing inspection processes.

- Site Mapping and Progress Tracking: Drones equipped with cameras and LiDAR autonomously scan construction sites. They create precise 3D models. They also track progress against the BIM model, identifying deviations early on.

- Structural Inspection: Drones and ground-based mobile robots inspect hard-to-reach areas. For instance, they check bridges, tall buildings, or confined spaces. They can detect cracks, corrosion, or other anomalies. This ultimately improves safety and maintenance planning.

- Safety Monitoring: Robots can monitor site safety. They identify hazards, detect unauthorized entry into dangerous zones, or track worker movements to prevent accidents.

D. Logistics & Material Handling:

Robotics also streamline the movement of materials.

- Autonomous Material Transport: Self-driving vehicles and robots transport materials across large construction sites. They optimize delivery routes and reduce congestion, leading to more efficient operations.

- Robotic Arms for Lifting/Placing: Large robotic arms can precisely lift and place heavy or awkward components. This reduces manual labor, and importantly, improves safety on site.

E. Exoskeletons:

While not fully autonomous robots, exoskeletons are wearable robotic devices. They assist human workers. By reducing fatigue and preventing injuries, they enable workers to lift heavy objects with less strain or perform repetitive tasks more easily. This technology enhances human capability.

This wide range of applications clearly demonstrates how Construction Robotics is fundamentally changing every aspect of building, ensuring greater efficiency and safety.

IV. Key Benefits of Embracing Construction Robotics

The integration of Construction Robotics offers compelling advantages for the industry. These benefits lead to significant improvements across various operational areas.

- Enhanced Productivity & Speed: Robots work tirelessly, 24/7, without breaks. Consequently, this accelerates construction timelines significantly. Tasks are completed faster, directly leading to quicker project delivery and earlier revenue generation.

- Improved Safety: This is arguably the most crucial benefit. Robots perform hazardous tasks. These include working at heights, in confined spaces, or with heavy loads. This dramatically reduces human exposure to accidents and injuries, making sites safer for all personnel.

- Higher Quality & Precision: Robots execute tasks with extreme accuracy. They follow digital models precisely. This minimizes errors and ensures consistent quality. Indeed, they achieve tolerances that are difficult to match manually, resulting in superior finished products.

- Cost Efficiency: While the initial investment can be high, Construction Robotics can lead to substantial long-term cost savings. These include reduced labor costs, less material waste due to precision, and fewer rework expenses. Furthermore, faster project completion also reduces overheads.

- Addressing Labor Shortages: Many regions globally face a shortage of skilled construction labor. Robotics can effectively fill these gaps. They maintain productivity levels and ensure project continuity even when human resources are scarce.

- Enabling Complex Designs: Robots can execute intricate, non-standard geometries with ease. This facilitates the realization of innovative architectural and structural designs. Such designs might otherwise be too complex or costly for traditional methods.

V. Challenges and Considerations for Adoption:-

Despite its immense promise, the widespread adoption of Construction Robotics faces several hurdles. Students and future engineers must be aware of these challenges.

- Initial Investment Cost: The upfront capital expenditure for purchasing, deploying, and maintaining advanced robots can be substantial. This factor often makes adoption challenging, particularly for smaller firms or those with limited access to capital.

- Integration with Existing Workflows: Seamlessly integrating robots into current construction workflows requires careful planning. This includes ensuring compatibility with BIM models, managing site logistics efficiently, and adapting supply chain management. Interoperability between various systems remains a key concern.

- Regulatory & Safety Standards: New regulations and safety standards are urgently needed. These must govern human-robot interaction on dynamic construction sites. Establishing clear guidelines for safe co-working environments is paramount for widespread adoption.

- Skilled Workforce Development: The shift to robotics demands new skill sets from the workforce. Workers need comprehensive training in robot operation, maintenance, programming, and data analysis. This necessitates significant investment in education and upskilling programs.

- Site Environment Complexity: Construction sites are often unstructured and dynamic. This presents unique challenges for autonomous robots. They must navigate uneven terrain, changing weather conditions, and unexpected obstacles effectively.

- Public Perception & Job Displacement Concerns: There are legitimate concerns about job displacement as robots take over manual tasks. The industry must manage this perception effectively. It must emphasize job transformation and the creation of new, higher-skilled roles in robot operation and management.

VI. The Future of Construction Robotics: A Student’s Outlook

For students entering civil and structural engineering, understanding Construction Robotics is crucial. The future workforce will undoubtedly operate alongside, rather than solely instead of, these intelligent machines.

- Interdisciplinary Skills: Develop a strong blend of engineering knowledge with robotics, artificial intelligence, and programming skills. Understanding control systems, automation software, and data analytics will prove invaluable.

- Focus on Human-Robot Collaboration: The emphasis is increasingly shifting towards human-robot collaboration (cobots). Learn how to design systems where humans and robots work together efficiently and safely, leveraging the strengths of both.

- Designing for Automation: Consider how designs can be specifically optimized for robotic fabrication and assembly. This involves promoting modularity, standardizing components, and incorporating features that facilitate robotic handling and construction.

- Ethical Considerations: Engage deeply with the ethical implications of automation. This includes discussing potential job impacts, safety responsibilities, and ensuring the equitable distribution of technological benefits across society.

This is truly a smart gateway to a future-ready AEC career. The future of structural engineering is being built with these intelligent machines, and you, as a student, have a pivotal role to play.

Conclusion: Robotics as a Game-Changer

Construction Robotics is unequivocally a game-changer for the civil and structural engineering sectors. Moving far beyond the initial fascination with 3D printing, the industry is now witnessing the broad deployment of intelligent, autonomous, and semi-autonomous machines across diverse tasks. From laying bricks with unparalleled precision to inspecting remote infrastructure, robots are enhancing productivity, dramatically improving safety, and ensuring higher quality in construction projects worldwide.

For aspiring engineers, this transformation signifies a dynamic and exciting career path. The future construction site will undoubtedly be a collaborative environment. Humans and robots will work in synergy. This will lead to unprecedented levels of efficiency and innovation. Embracing Construction Robotics means preparing for a future where technology and human expertise combine to build the resilient, sustainable, and complex structures of tomorrow. Your journey into this field will be at the forefront of this exhilarating revolution. The future of structural engineering is bright and innovative, driven by these very trends.

FAQ’s

Q1: How do Construction Robotics differ from traditional construction machinery?

A1: Traditional machinery performs pre-programmed, often single-function tasks. Construction robots, however, possess sensing capabilities, processing power, and adaptability. They can perform complex, multi-faceted tasks autonomously or semi-autonomously, responding to dynamic site conditions.

Q2: What is an example of Construction Robotics beyond 3D printing?

A2: A prominent example is robotic bricklaying. Robots can lay bricks with much greater speed and precision than human masons, accurately following digital plans. Other notable examples include robotic welding, autonomous excavation, and drones for site inspection and mapping.

Q3: Are construction robots designed to fully replace human workers?

A3: Not primarily. While robots automate repetitive or dangerous tasks, the predominant trend is towards human-robot collaboration (cobots). Robots augment human capabilities, improve safety, and address labor shortages, allowing human workers to focus on higher-value, more complex tasks.

Q4: What are the main benefits of using Construction Robotics?

A4: Key benefits include enhanced productivity and speed, significantly improved safety by removing humans from hazardous tasks, higher quality and precision in execution, long-term cost efficiency through reduced waste and labor, and the ability to address skilled labor shortages in the industry.

Q5: What skills are important for students interested in Construction Robotics?

A5: Students should develop interdisciplinary skills. This includes a strong foundation in civil/structural engineering, combined with knowledge of robotics, artificial intelligence, programming (e.g., Python), computational design, and data analysis. Understanding human-robot interaction is also becoming vital for future roles.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.