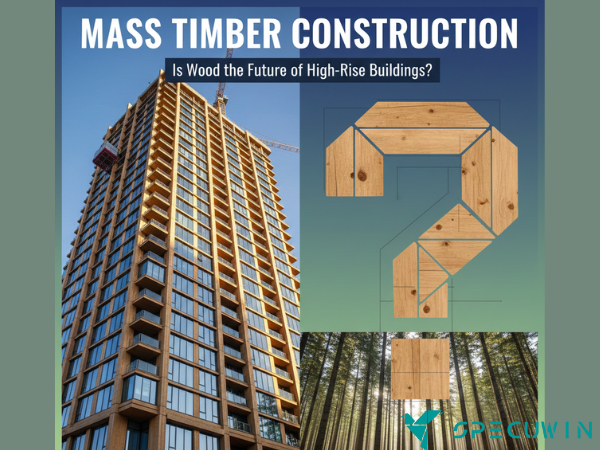

For over a century, the recipe for a skyscraper has been predictable: pour a massive concrete foundation, erect a skeleton of steel, and wrap it in glass. It’s a formula that built New York, Chicago, and Dubai. But recently, a quiet revolution has been growing in the forests and factories of the architectural world. It is the resurgence of wood not the 2x4s of suburban housing, but engineered, massive panels capable of supporting immense loads. This movement, known as Mass Timber Construction, is challenging our assumptions about what high-rise buildings can be.

As the AEC industry grapples with the urgent need to reduce carbon footprints, architects and engineers are looking back to one of humanity’s oldest building materials, reinvented for the 21st century. But is this just a trend, or is it a viable structural evolution? In this deep dive, we will explore the engineering wizardry behind Cross-Laminated Timber (CLT) and Glulam, and why Timber Construction might just be the key to a sustainable urban future.

The Evolution of Mass Timber Construction:-

To understand where we are going, we have to look at how we got here. For decades, wood was relegated to low-rise residential projects due to fire codes and structural limitations. However, the development of engineered wood products has changed the game entirely. We are no longer talking about raw lumber; we are talking about precision-engineered components that rival the strength of steel and concrete.

This shift is part of a broader trend in the industry to explore alternative materials. As we move beyond traditional methods, professionals are increasingly adopting Modern materials in structural engineering beyond concrete and steel , and mass timber is leading that charge. The “mass” in mass timber refers to the sheer bulk of these engineered wood products, which provides them with their unique structural and fire-resistant properties.

Core Technologies in Mass Timber Construction:-

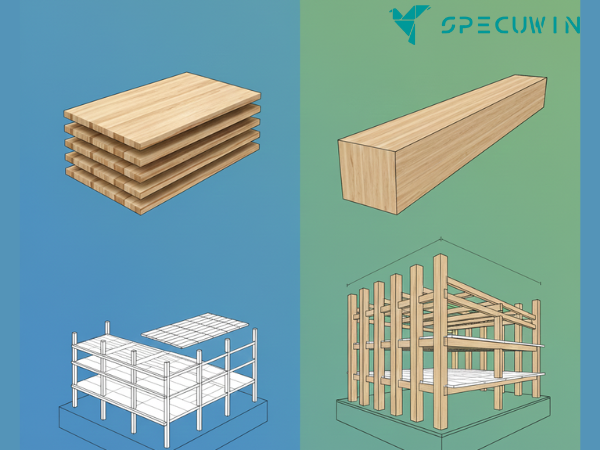

The term “mass timber” covers a family of engineered wood products, but two specific technologies are doing the heavy lifting in today’s high-rises: Cross-Laminated Timber (CLT) and Glued Laminated Timber (Glulam). Understanding the distinction between them is vital for anyone interested in Timber Construction.

Cross-Laminated Timber (CLT) in Timber Construction:

Think of CLT as “plywood on steroids.” It consists of layers of kiln-dried lumber boards stacked in alternating directions—one layer running lengthwise, the next crosswise and bonded with structural adhesives. This cross-lamination provides immense dimensional stability.

In a typical Timber Construction project, CLT is used primarily for panelized applications: floors, walls, and roofs. Because the grain runs in two directions, the panels have high strength and stiffness in both axes, making them act similarly to a precast concrete slab but with a fraction of the weight. This weight reduction allows for smaller foundations and is particularly beneficial when building on soils with lower bearing capacity.

Glued Laminated Timber (Glulam) in Timber Construction:

While CLT is the slab and the wall, Glulam is the beam and the column. Glulam is made by bonding layers of timber (laminae) together with durable, moisture-resistant adhesives. Unlike CLT, the grain of all laminations runs parallel to the length of the member.

This alignment maximizes longitudinal strength, making Glulam ideal for long-span structural members. In modern Timber Construction, you will often see a skeleton of Glulam columns and beams supporting CLT floor plates. This combination allows for open floor plans and the soaring aesthetic spaces that architects love, all while maintaining structural rigor.

Structural Integrity and Safety in Mass Timber Construction:-

The most common skepticism regarding wood in high-rises revolves around safety. “Won’t it burn?” and “Is it strong enough?” are the first questions clients ask. The answers lie in the physics of large-mass wood.

Fire Resistance:

It is counterintuitive, but mass timber performs exceptionally well in fire. Unlike light-frame wood construction (like a standard house) which burns quickly, mass timber is… massive. When exposed to fire, the outer layer of the wood chars. This char layer acts as an insulator, protecting the inner core of the wood from the heat and preserving its structural integrity for a predictable amount of time.

Seismic Resilience:-

Wood has a high strength-to-weight ratio and natural ductility. In an earthquake, a heavy concrete building generates massive inertial forces that the structure must resist. A mass timber building, being significantly lighter, experiences lower seismic forces. Furthermore, the connections in Timber Construction can be designed to yield and dissipate energy. For engineers looking to push the boundaries of safety, this material offers exciting possibilities, Aligning with current innovations in earthquake-resistant design .

Sustainability: The Heart of Mass Timber Construction:-

The strongest argument for switching to wood is environmental. The construction industry is a massive contributor to global CO2 emissions, largely due to the production of steel and concrete. Concrete production alone accounts for about 8% of global CO2 emissions.

Trees, however, grow by absorbing carbon dioxide. When we harvest that tree and turn it into a building, that carbon remains sequestered in the structure for the life of the building. This transforms buildings from carbon emitters into carbon vaults.

- Renewable Resource: Unlike finite minerals, timber can be grown and harvested in a sustainable cycle.

- Reduced Embodied Energy: The energy required to harvest, transport, and manufacture timber products is significantly lower than that of steel or concrete.

- Biophilic Design: Beyond the carbon math, wood interiors have been shown to improve occupant well-being, reducing stress and increasing productivity.

For firms dedicated to eco-friendly practices, adopting mass timber is a Logical step toward creating sustainable structures and eco-friendly approaches in modern construction.

The Future Outlook for Timber Construction:-

We are currently witnessing a “space race” of wooden skyscrapers, with taller structures emerging in Norway, Canada, and Austria. Codes are updating to reflect the safety data; the International Building Code (IBC) has recently introduced changes allowing mass timber buildings up to 18 stories tall.

However, the transition isn’t without hurdles. The supply chain for mass timber is still maturing, and not every region has local manufacturing capabilities. Additionally, there is a “knowledge gap” in the labor force; contractors need to learn the specific handling and moisture protection requirements of wood.

As we look ahead, the role of the structural engineer is evolving. It requires a deep understanding of these new materials and a willingness to innovate. This Shift is a key component of the future of structural engineering trends and innovations . The buildings of tomorrow may not be defined by the cold grey of concrete, but by the warm, sustainable strength of Timber Construction.

FAQs:-

1. Is Mass Timber Construction as strong as concrete and steel?

A. Yes, for its weight, mass timber is incredibly strong. While the material properties are different, engineered products like CLT and Glulam are designed to meet the same rigorous structural load requirements as steel and concrete for the buildings they are approved for.

2. How does Timber Construction handle fire safety?

A. Mass timber relies on “charring.” In a fire, the outer surface burns and turns to charcoal, which insulates the unburnt wood core. This slows the combustion process significantly, allowing the structure to remain standing for hours, giving occupants time to evacuate and firefighters time to work.

3. Is mass timber cheaper than traditional construction?

A. Currently, the material costs for mass timber can be higher than concrete. However, because the pieces are prefabricated and lighter, the construction speed is much faster (often 25% faster), and foundation costs are lower. This can result in overall project savings or cost parity.

4. What is the difference between CLT and standard lumber?

A. Standard lumber consists of single sawn pieces of wood (like a 2×4). CLT is a composite panel made of multiple layers of lumber glued together at 90-degree angles. This makes CLT dimensionally stable (it doesn’t warp easily) and capable of acting as a load-bearing wall or floor, unlike standard lumber which requires a frame.

5. How does Mass Timber Construction impact the environment?

A. It has a significantly lower carbon footprint than steel or concrete. Wood sequesters carbon (stores it) rather than emitting it. If the timber is sourced from sustainably managed forests, it is one of the most eco-friendly building methods available today.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.