Building a home or a commercial space is already a high-stakes financial juggling act. You have contractors to manage, timelines to meet, and materials to source. But there is a silent budget-killer that often goes unnoticed until the bills start piling up: Over design.

We all want our buildings to be safe. No one argues with the need for stability and durability. However, there is a fine line between a safe structure and a wasteful one. When an engineer specifies beams that are twice as heavy as necessary or foundations deep enough for a skyscraper when you’re building a two-story home, you aren’t just paying for “extra safety” you are paying for fear, inefficiency, or a lack of optimization.

In this guide, we will break down what Over design really looks like, why it happens, and how you can ensure your project remains structurally sound without burying your budget in unnecessary concrete and steel.

What Exactly is Structural Over Design?:-

To understand Over design, you first have to understand the job of a structural engineer. Their primary mandate is life safety. They calculate the loads wind, snow, furniture, people and size the structural elements to support those loads with a margin of error.

However, “conservative engineering” becomes problematic when that margin of error is arbitrarily inflated. It occurs when a professional ignores precision in favor of a “one-size-fits-all” approach. Instead of calculating the exact requirement for a specific beam, they might pick the largest size just to be safe, skipping the detailed analysis that would save materials.

This isn’t just about technical laziness; it is often a misunderstanding of the role. A great engineer balances safety with economy.

Suggested Internal Link: To understand the baseline of what you should expect, read more about What is the role of a structural engineer .

The Real Cost of Over Design in Residential and Commercial Projects:-

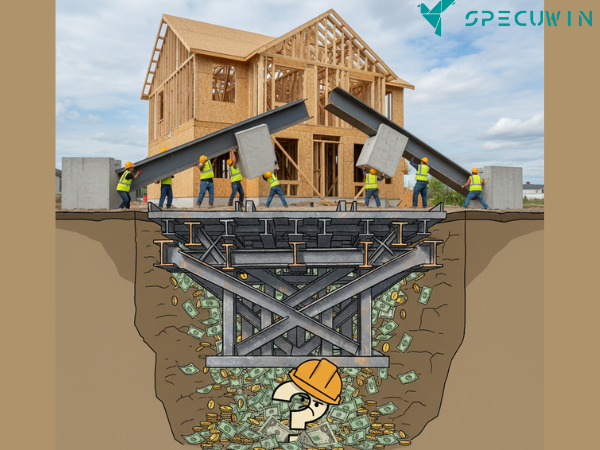

The financial impact of Over design is rarely a single line item on an invoice. It is hidden inside the volume of materials you purchase.

- Material Waste: If your columns are 20% larger than required, you are paying for 20% more concrete, rebar, and finishing materials.

- Labor Increases: Heavier steel beams might require cranes instead of manual lifting, or larger crews to install.

- Foundation Creep: A heavier superstructure puts more load on the foundation. Suddenly, your footings need to be wider and deeper, compounding the cost.

For example, in material selection, opting for high-grade steel where standard grade would suffice is a classic symptom. It’s vital to understand how these choices ripple through your budget.

Why Does Structural Over Design Happen?:-

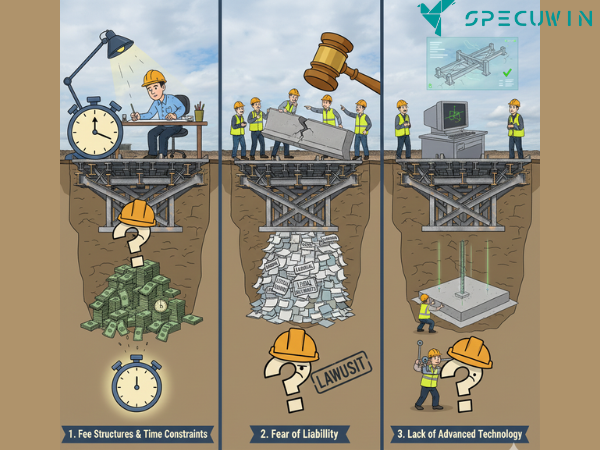

If optimization saves money, why doesn’t every engineer do it? The reasons are usually human, not mathematical.

1. Fee Structures and Time Constraints Many engineers work on fixed fees. Optimizing a complex structure takes time—time that eats into their profit margin. It is much faster to apply a “rule of thumb” that guarantees safety but ignores efficiency. If you rush the design phase, you often pay for it during construction.

2. Fear of Liability We live in a litigious world. Some engineers are terrified of lawsuits. To protect themselves, they add layers of redundancy that go far beyond code requirements. While you want a safe building, you shouldn’t have to bankroll their anxiety.

3. Lack of Advanced Technology Firms that haven’t updated their tech stack often rely on manual calculations or outdated software that cannot run complex simulations. Modern tools allow for “lean” designs that remain incredibly strong.

How to Identify Over Design in Your Blueprints:-

You don’t need a degree in physics to spot potential Over design. As a client, you can look for red flags and ask intelligent questions.

- Repetition: Does every single beam on the floor plan look exactly the same size, even though some span 20 feet and others only span 5 feet? That is a sign the engineer didn’t calculate them individually.

- Crowded Rebar: If the reinforcement in your drawings looks so dense that you wonder how the concrete will even flow between the bars, ask about it.

- Vague Details: Drawings that lack specific details and rely on “typical” notes often lean on heavy, conservative assumptions.

If you are unsure, it is often worth getting a second opinion. A structural peer review might cost a few thousand dollars but could save tens of thousands in construction costs.

Mitigating Over Design Through Collaboration:-

The best way to avoid this issue is to foster a relationship between your build team and your design team early on. When contractors and engineers talk, magic happens. A contractor might say, “If you reduce this beam depth by two inches, we can avoid a custom ceiling fitting.”

When the engineer works in a silo, they don’t see the cost implications of their lines on paper. Bringing them into the conversation with the builders allows for “value engineering” the process of maintaining function while reducing cost.

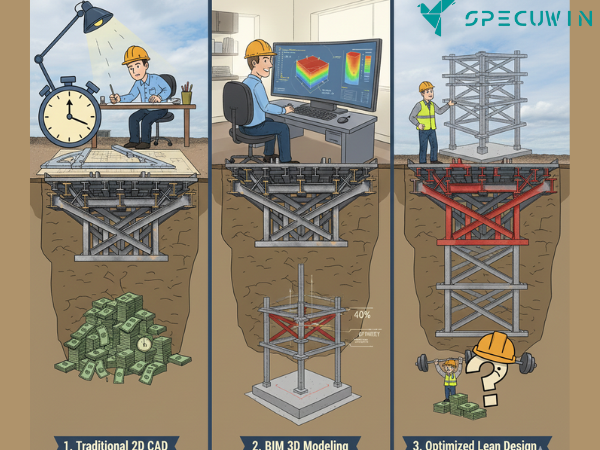

The Role of BIM in Preventing Over Design:-

Building Information Modeling (BIM) is perhaps the greatest weapon against inefficiency. Unlike 2D CAD drawings, BIM creates a 3D model that can simulate loads and stresses with high precision.

With BIM, an engineer can visualize exactly where the stress points are. They can see that a column is only utilizing 40% of its capacity and can safely reduce its size. It moves the process from “guessing and doubling it” to “calculating and optimizing it.”

If your engineer isn’t using BIM or advanced 3D modeling, they might be leaving money on the table your money. If you are new to this concept, read BIM for beginners: a guide to getting started.

Is Sustainability a Victim of Over Design?:-

Finally, we must talk about the planet. Over design isn’t just bad for your wallet; it’s terrible for the environment. The construction industry is a massive consumer of global resources.

Every extra cubic meter of concrete represents significant carbon emissions. By demanding optimized engineering, you are actually building a “greener” structure simply by using less stuff. You don’t always need expensive eco-gadgets to be sustainable; sometimes, you just need efficient math.

Read more on:-Sustainable structures and eco-friendly approaches in modern construction.

Conclusion: Don’t Settle for Over Design:-

Your building needs to stand up for a hundred years, but it doesn’t need to be built like a bunker if it’s a coffee shop. Over design is a habit of the past, driven by manual calculation limitations and risk aversion.

As a client, you have the right to ask, “Is this the most efficient way to build this?” Empower yourself with knowledge, demand collaboration between your teams, and insist on modern analysis methods. Your budget will thank you.

FAQ’s:-

1. Is structural Over design illegal?

A. No, it is not illegal. As long as the building meets the minimum safety codes, an engineer can make it as strong (and heavy) as they like. However, it is considered poor practice and unethical if it causes the client unnecessary financial loss due to laziness or lack of expertise.

2. How much can I save by fixing Over design?

A. Savings vary, but “Value Engineering” (the process of cutting out waste) can typically reduce the structural shell cost by 10% to 20%. On large commercial projects, this can amount to hundreds of thousands of dollars.

3. Will optimizing the design make my building less safe?

A. Not if done correctly. Optimization means reducing the “fat” while keeping the “muscle.” The goal is to meet the safety code requirements precisely, rather than exceeding them by an arbitrary 200%.

4. Can I ask my contractor to reduce the beam sizes?

A. Never let a contractor change structural sizes without the engineer’s approval. Contractors know costs, but they don’t run the load calculations. The correct approach is to have the contractor suggest changes, which the engineer then verifies and stamps.

5. Does using BIM software guarantee there is no Over design?

A. Not automatically. BIM is a tool, not a magic wand. If the engineer using the software inputs conservative assumptions or doesn’t know how to use the optimization features, you can still end up with a wasteful design. However, it makes spotting and fixing these issues much easier.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.