In today’s rapidly evolving technological landscape, facility management (FM) and operations are undergoing a significant transformation. One of the most compelling drivers of this change is the emergence and increasing sophistication of digital twins. These virtual replicas of physical assets, processes, or even entire facilities are revolutionizing how organizations plan, manage, and optimize their built environments. This blog post will delve into the profound impact of digital twins on facility management and operations, exploring their benefits, applications, and the future they are shaping.

Understanding Digital Twins:-

At its core, a digital twin is a dynamic virtual representation of a physical entity. Unlike static Building Information Models (BIM), which are often used for design and construction, digital twins are continuously updated with real-time data from various sources, including IoT sensors, building management systems (BMS), maintenance logs, and even human input. This constant data flow allows the digital twin to mirror the real-world performance and condition of the asset or facility with remarkable accuracy.

Think of it as a living, breathing digital counterpart that provides a holistic and up-to-the-minute view of everything happening within a physical space. This comprehensive understanding empowers facility managers and operations teams to make more informed decisions, predict potential issues, and ultimately enhance efficiency and sustainability. The integration of BIM is often the first step in creating a digital twin, laying the foundational data before real-time operational information is layered on top. This seamless transition from design to operations is a key differentiator.

Key Benefits of Digital Twins in Facility Management:-

The adoption of digital twin technology offers a multitude of advantages for facility management and operations:

1. Enhanced Asset Management and Predictive Maintenance:

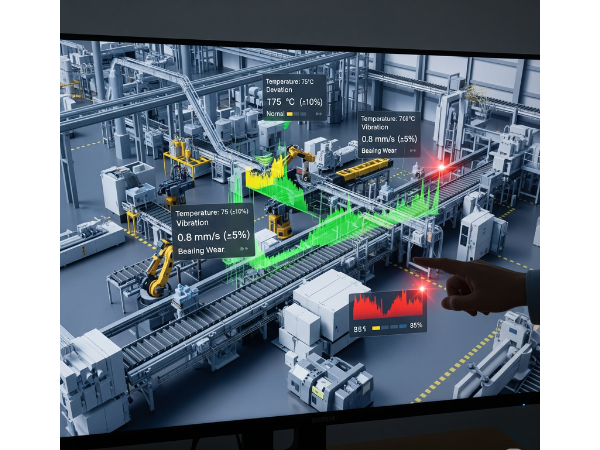

A digital twin provides a centralized platform for managing all facility assets, from HVAC systems and electrical equipment to furniture and fixtures. By integrating real-time sensor data, facility managers can gain deep insights into asset performance, identify anomalies, and predict potential failures before they occur. This proactive approach allows for predictive maintenance, scheduling interventions based on actual asset conditions rather than fixed time intervals. This not only reduces costly downtime but also extends the lifespan of critical assets, maximizing return on investment.

2. Optimized Space Utilization and Occupant Experience:

One of the most valuable applications of a digital twin is its ability to analyze and optimize how space is used. By collecting data on occupancy, movement patterns, and environmental conditions, facility managers can identify underutilized areas, reconfigure layouts for better flow, and create more comfortable and productive environments. The twin can simulate different scenarios, such as moving a department or adding new equipment, to assess their impact before any physical changes are made. This data-driven approach ensures that spaces are used as efficiently as possible, directly impacting both operational costs and employee satisfaction.

3. Improved Energy Efficiency and Sustainability:

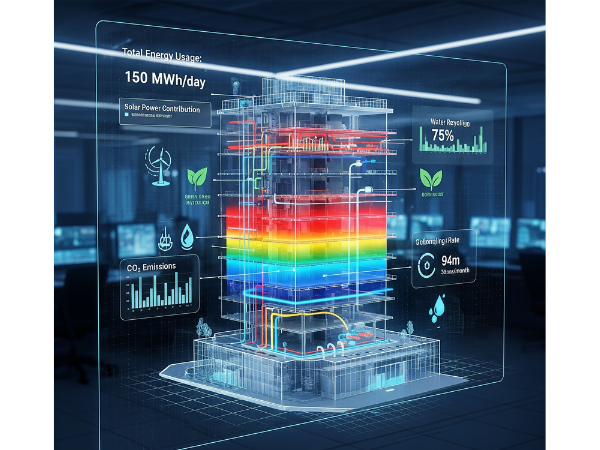

Sustainability is a growing priority for organizations, and digital twins are a powerful tool for achieving eco-friendly goals. By modeling a building’s energy consumption in real-time, the twin can simulate the effects of different operational changes, such as adjusting lighting schedules, optimizing HVAC systems, or integrating renewable energy sources. This capability allows facility managers to identify and implement the most impactful energy-saving strategies, leading to significant reductions in utility costs and a smaller carbon footprint. The ability to model the long-term effects of material selection and design choices also helps in creating more sustainable structures from the outset.

4. Streamlined Operations and Incident Response:

A digital twin acts as a central hub for all operational data, providing a single source of truth for facility managers. In the event of an emergency, such as a fire or a system failure, the twin can provide critical real-time information to first responders, including the location of occupants, fire suppression systems, and potential hazards. The twin can also automate routine tasks and provide a comprehensive view of maintenance history, simplifying compliance and reporting. This operational streamlining reduces human error and enhances overall safety and efficiency.

5. Better Lifecycle Management:

From the initial design phase to demolition, a facility goes through a complete lifecycle. A digital twin can capture and maintain data throughout this entire journey, ensuring that knowledge is not lost over time. This continuous data stream, starting from the BIM model, provides a comprehensive historical record of all maintenance, renovations, and performance metrics. This valuable insight is crucial for long-term planning, budgeting for capital expenditures, and making informed decisions about the future of the facility. The ability to structure and connect data digitally, much like in BIM for bridge design, provides a robust framework for managing complex assets.

The Role of Technology in Powering Digital Twins:-

The effectiveness of a digital twin is dependent on a sophisticated technology stack:

- Internet of Things (IoT): A vast network of sensors, meters, and connected devices forms the eyes and ears of the twin, collecting real-time data on temperature, occupancy, air quality, energy consumption, and asset performance.

- Building Information Modeling (BIM): The foundational 3D model that provides the geometric and semantic data of the facility. Without a detailed BIM model, the digital twin would lack its physical context and accuracy. For those considering a career in the field, understanding this connection is crucial.

- Artificial Intelligence (AI) and Machine Learning (ML): These technologies analyze the massive datasets collected by the twin to identify patterns, predict failures, and recommend optimizations. AI is what turns raw data into actionable insights.

- Cloud Computing: The scalability and processing power of the cloud are essential for storing and analyzing the large volumes of data generated by a digital twin.

Challenges and the Future of Digital Twins:-

While the benefits are clear, the adoption of digital twins is not without its challenges. Initial implementation can be complex and expensive, requiring significant investment in sensors, software, and data integration. Cybersecurity is also a major concern, as the vast network of connected devices creates new vulnerabilities.

However, as the technology becomes more accessible and cost-effective, the future looks incredibly bright. We can expect to see digital twins become standard practice in new construction, and the retrofitting of older buildings will become more common. Future applications will extend beyond single buildings to entire campuses, smart cities, and infrastructure, all working together to create a more efficient, sustainable, and resilient world. The trends and innovations we see in structural engineering today are a clear indicator of this future.

FAQ’s:-

Q1: What is a digital twin?

A: A digital twin is a dynamic, virtual replica of a physical asset, process, or system. It is constantly updated with real-time data from sensors and other sources, allowing it to accurately mirror the real-world performance and condition of its physical counterpart.

Q2: How do digital twins differ from BIM?

A: Building Information Modeling (BIM) is a static, data-rich 3D model primarily used for design and construction. A digital twin builds on the BIM model by adding real-time, operational data, making it a living, continuously updated representation used for ongoing management and optimization.

Q3: What are the main benefits of using a digital twin in facility management?

A: The main benefits include enhanced predictive maintenance, optimized space utilization, improved energy efficiency, streamlined operations, and better long-term lifecycle management of assets and facilities.

Q4: What technologies are required to create a digital twin?

A: A digital twin relies on a combination of technologies, including IoT sensors for data collection, Building Information Modeling (BIM) for the foundational model, AI and machine learning for data analysis, and cloud computing for data storage and processing.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.