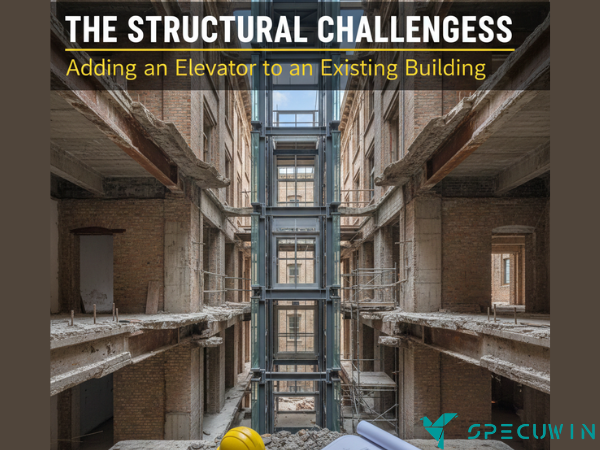

Adding an elevator to an older structure is one of the most transformative upgrades a property owner can undertake. Whether it’s improving accessibility for an aging population, increasing property value, or complying with modern building codes, the benefits are undeniable. However, the path to vertical mobility is rarely a straight line. The primary hurdle isn’t just the machinery itself, but the significant structural challenges that arise when you attempt to carve a vertical shaft through a building that was never designed to house one.

From the foundation to the roofline, every floor is part of a delicate load-bearing ecosystem. Disrupting that ecosystem requires surgical precision, expert engineering, and a deep understanding of historical construction methods. In this guide, we will explore the technical realities, the safety considerations, and the innovative solutions used to overcome these complex structural challenges.

Assessing the Foundation: The First of Many Structural Challenges:-

Before an elevator can go up, the building’s base must be able to handle the weight coming down. Most people assume an elevator “hangs” from the top, but the reality is that the elevator pit and the hoistway walls transfer significant concentrated loads to the ground.

1. Soil Bearing Capacity and Pit Excavation:

One of the most immediate structural challenges is the excavation of the elevator pit. Most elevators require a pit between 4 to 6 feet deep. In an existing building, digging this hole often means working dangerously close to existing footings. If the soil is sandy or the water table is high, the risk of undermining the building’s current foundation is a massive concern.

Engineers must often implement “underpinning” a process of strengthening the existing foundation before the pit can even be dug. This ensures that the new concentrated load of the elevator doesn’t cause the building to settle unevenly.

2. Load Redistribution:

The new elevator shaft whether made of steel or masonry acts as a new vertical column. In many older buildings, the existing slabs were only designed for “live loads” like furniture and people. Supporting the dead weight of a concrete elevator shaft represents one of the major structural challenges in retrofitting, requiring a brand-new foundation pad specifically for the lift.

Cutting Through the Skeleton: Floor Plate Structural Challenges:-

Perhaps the most nerve-wracking phase of an elevator retrofit is the “big cut.” To create a hoistway, you must remove a section of every floor from the roof to the basement.

1. Lateral Stability and Diaphragm Action:

Buildings are more than just stacks of floors; they are integrated systems where floors act as “diaphragms” that hold the walls together. When you cut a large hole for an elevator, you weaken that diaphragm. This creates structural challenges related to the building’s ability to resist wind or seismic forces.

If the building is in a high-risk zone, this is even more critical. Engineers must often add steel “headers” and “trimmers” around the new opening to restore the floor’s integrity. This is similar to the care taken in Innovations in earthquake-resistant design.

2. Dealing with Load-Bearing Walls:

If your ideal elevator location happens to sit on a load-bearing wall, the structural challenges multiply. You aren’t just cutting a hole; you are removing a leg of the building. In these cases, massive steel beams must be installed to bridge the gap and transfer those loads to other parts of the structure before the wall is demolished.

Space Constraints and Hoistway Structural Challenges:-

Older buildings were built for efficiency of space, not for the inclusion of 21st-century machinery. Finding a “clear run” from top to bottom is rarely easy.

1. Alignment and Plumbness:

A modern elevator car moves at high speeds and requires a perfectly vertical (plumb) shaft. Older buildings, however, have often shifted, tilted, or settled over decades. One of the quiet structural challenges is realizing the building is slightly leaning. If the shaft isn’t perfectly straight, the elevator rails cannot be installed correctly, leading to mechanical failure or a very bumpy ride.

2. Overhead Clearance:

At the top of the shaft, the elevator needs “overrun” space room for the car to safely stop above the highest floor. Many existing buildings have low rooflines. This presents structural challenges that may require extending the shaft through the roof, creating a “doghouse” or penthouse structure on the top of the building. This changes the building’s silhouette and requires new roofing and waterproofing details to prevent leaks.

Material Compatibility: Modern Tech vs. Old Bones:-

When you introduce modern reinforced concrete or heavy steel into a building made of timber or unreinforced masonry, the materials don’t always play nice together.

1. Thermal Expansion and Rigidity:

Modern materials are often much stiffer than historical ones. One of the structural challenges is ensuring that the new, rigid elevator shaft doesn’t cause the older, more flexible parts of the building to crack during temperature changes or minor tremors. Engineers must design “slip joints” or specific connection points that allow for a degree of independent movement between the old and the new.

For more on how material choice affects these outcomes, you might find interest in the impact of material selection on structural integrity.

External Retrofits: When Internal Structural Challenges Are Too High:-

Sometimes, the interior of a building is so tightly packed or historically significant that cutting through the floors is impossible. In these scenarios, the solution is an external elevator tower.

1. Building Ties and Lateral Loads:

While an external tower solves the “cutting holes” problem, it introduces new structural challenges. The tower must be “tied” to the existing building so it doesn’t pull away. However, because the tower and the building sit on different foundations, they may settle at different rates. If the ties are too rigid, the settling of one can literally pull bricks out of the other.

The Role of Professional Analysis:-

Because of these layers of complexity, you cannot simply call an elevator company and ask for an installation. The process must begin with a structural engineer.

A thorough investigation often involving X-rays of the floor slabs or soil samples is required to map out the structural challenges before a single hammer is swung. Understanding The role of a structural engineer is vital here, as they act as the architect of safety for the entire project.

Owners should also learn How to read a structural engineering report to understand the specific risks identified for their property.

Conclusion:-

Retrofitting an elevator is a masterclass in compromise and clever engineering. While the structural challenges are significant ranging from foundation reinforcement to maintaining lateral stability they are not insurmountable. By respecting the original “bones” of the building and using modern reinforcement techniques, we can bring 21st-century convenience to historical gems.

Ultimately, overcoming these structural challenges is an investment in the building’s longevity, ensuring it remains accessible and functional for generations to come.

FAQ’s:-

1. Can any old building support an elevator?

A. Almost any building can, but the cost varies wildly based on the structural challenges. Timber-frame buildings might need more lateral bracing, while masonry buildings might require extensive underpinning.

2. What is the most expensive part of the structural work?

A. Usually, it is the foundation and pit excavation. If you hit bedrock or a high water table, the costs of managing those structural challenges can skyrocket.

3. Does an elevator shaft help or hurt the building’s strength?

A. If designed correctly, a concrete elevator shaft can actually act as a “shear core,” potentially making the building more resistant to wind and earthquakes.

4. How long does the structural phase take?

A. The structural modifications (cutting floors, reinforcing beams, pouring the pit) typically take 4 to 8 weeks, depending on the number of floors and the specific structural challenges encountered.

5. Do I need a structural inspection before starting?

A. Absolutely. You should look for top signs your building needs a structural inspection to identify any pre-existing weaknesses that could complicate the elevator installation.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.