The Lansdowne Road Stadium was more than just a sports venue; it was a century-old cauldron of history, passion, and the famous “Lansdowne Roar.” When the decision was made to replace the aging facility with a modern, world-class arena, the task was monumental, but the potential was electrifying. The new home for Irish football and rugby needed to be grand, seating 50,000 spectators, yet it had to sit humbly in a notoriously cramped and restrictive urban Dublin neighborhood known as Aviva Stadium. This was not a project for concrete slabs and straight lines; it demanded a building that could breathe, flex, and respond to its intimate surroundings.

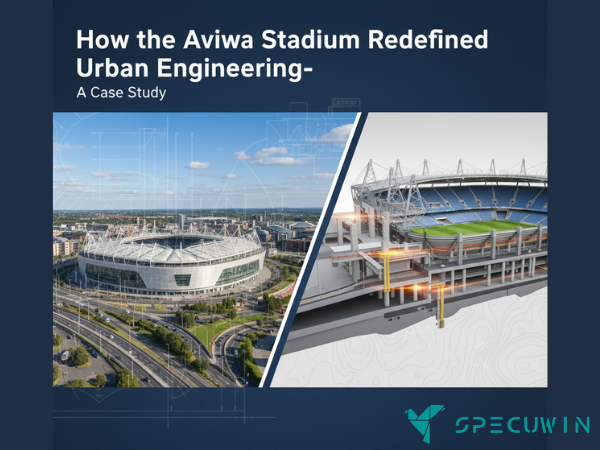

The resulting architectural marvel, the Aviva Stadium, is a testament to what happens when human ingenuity meets technological breakthrough. It’s a structure defined by its constraints, with a unique, undulating, ‘crystal bowl’ form that simultaneously maximizes capacity, respects residential boundaries, and stands as an unforgettable icon on the Dublin skyline. The success of the Aviva Stadium case study lies not just in the beautiful finished product, but in the pioneering process of integrated parametric design that brought its complex curves to life, effectively setting a new global standard for stadium construction.

The Constrained Canvas: A Design Challenge Unique to Aviva Stadium:-

The site of the new Aviva Stadium was, structurally and logistically, a nightmare waiting to happen. To fulfill the client’s brief of a 50,000-seat international arena, the design team led by architects Populous (formerly HOK Sport) and Scott Tallon Walker, alongside structural engineers Buro Happold faced a gauntlet of non-negotiable limitations.

The Low-Lying North Stand and Respecting the Neighbors:

The most significant design constraint was the proximity of two-story residential homes directly to the north of the site. The architects knew that a towering structure would be intrusive, casting a permanent shadow and stripping the adjacent gardens of daylight. The human, empathetic solution was radical: drop the northern stand to a single tier, dramatically lowering the height of the entire building on that side.

This decision was the genesis of the stadium’s distinctive shape. The bowl geometry grows from a single tier in the north to four tiers on the east, south, and west sides. This sweeping, organic form not only minimizes the stadium’s visual impact but also allows maximum natural light into the adjacent neighborhood and the concourse areas. The translucent, shingled skin that wraps the exterior seamlessly connects the roof and façade, helping to reduce the visual mass and creating a highly atmospheric experience inside the seating bowl.

A Site Bisected by Rail and River:

Beyond the residential constraints, the site was a dense, urban puzzle. The stadium footprint was bounded by the River Dodder on one side and bisected by the operational DART railway line on the west. The original west stand was built over the rail line, and the new design required major engineering works, including the demolition of the old stand and the creation of a new, integrated rail corridor and access podium for safe spectator movement. Every dimension, curve, and elevation of the Aviva Stadium had to be precisely reconciled with these immovable, physical realities.

Parametric Modeling: The Digital Blueprint for the Aviva Stadium’s Form:-

Faced with such complexity, the design team needed a tool that could handle endless variations and immediate feedback. The solution was a technological leap forward in stadium design: the use of a unified, commercially available parametric modeling system a groundbreaking approach that had never before been applied to a stadium project from inception to completion.

A Single Shared Model: The Power of Generative Components:

Parametric modeling (a core concept within BIM) defines geometry based on rules, relationships, and parameters rather than fixed coordinates. The structural engineers and architects shared a single model a central source of truth that became the conduit for all design information.

This shared digital platform, using software like Bentley’s Generative Components, allowed Buro Happold to define structural geometry, run analyses, and get rapid feedback on how their placement of columns or trusses impacted the architect’s vision, sightlines, and aesthetics. If the architect adjusted the exterior envelope, the engineer’s structural model could instantly upload the new parameters and redefine the steelwork accordingly. This approach drastically cut the overhead associated with design iterations, allowing for a detailed and swift exploration of options. It represents a massive paradigm shift in how design teams collaborate, moving From CAD to BIM and facilitating Enhanced project delivery.

Seamless Integration of Structure and Skin:

The parametric model was crucial in realizing the signature exterior skin. The façade and roof are not two separate entities, but one continuous, curving surface enveloped in over 19,000m² of translucent polycarbonate panels. This meant that the steel structure supporting the roof needed to precisely follow the architecturally defined control surface.

The parametric model ensured absolute coordination, automatically offsetting the truss top-chords to maintain a fixed distance from the façade’s architectural line, preventing clashes between the structural steel, the roof supports, and the cladding. The intricate geometry required 4,251 individually sized and shaped panels, which were managed and labeled using a precise coding system enabled by the 3D model, making on-site assembly accurate and efficient. This level of complex coordination highlights Why collaboration between contractors and structural engineers is key to successful projects.

Engineering Mastery: The Innovative Structure of the Aviva Stadium:-

The elegant exterior hides an incredibly robust and inventive structural solution. The complexity of the free-flowing form and the constraints of the site demanded engineering creativity, particularly in the design of the roof.

The Horseshoe Truss: A Load-Bearing Work of Art:

The roof structure is headlined by an innovative steel system featuring a colossal horseshoe truss. This primary truss spans the three higher tiers (East, South, and West), acting as the main load-bearing element.

To accommodate the low-lying north stand, the open end of the horseshoe is deliberately lower, resting on abutments that thrust its load directly into the ground. The rest of the immense load is managed by a structural hierarchy:

- A pair of tapering concrete super-columns supports the primary truss at the north end.

- Secondary spur-trusses transfer vertical loads from the primary truss back to a ring truss running along the perimeter.

- Tertiary trusses span between the primary and ring trusses, cantilevering up to 15 meters to form the slim, leading edge of the roof.

This complex, two-part roof design, which dips and curves to follow the architectural envelope, weighs approximately 150 kg/m² and successfully manages the massive forces from wind, snow, and the structure’s own weight, all while minimizing visual clutter in the seating bowl to protect spectator sightlines.

Sustainability Integrated: Green Design on a Grand Scale:

From the project’s inception, a commitment to minimizing environmental impact was central to the philosophy of the Aviva Stadium. This was achieved through conscious material selection and active conservation systems:

- Material Reuse and Recycling: Concrete from the demolition of the old stadium was crushed and reused as hardcore and sub-base material in the new construction. The old pitch’s topsoil was also stripped and reused on the new playing surface.

- Low-Carbon Construction: Low-carbon concrete, utilizing materials like blast-furnace slag, was used extensively in the exposed pre-cast and in-situ structures, saving an estimated 4,000 tonnes of CO₂.

- Rainwater Harvesting: The 19,000m² transparent roof acts as a massive collection surface. Rainwater is gathered and stored in 250,000-liter tanks in the basement, where it is treated and used for pitch irrigation and in the building’s waterless urinals, reducing demand on drinking water.

These details cement the Aviva Stadium as a landmark not just in structural engineering, but also in sustainable stadium development.

Conclusion:-

The Aviva Stadium officially opened in May 2010, replacing a beloved landmark with a futuristic icon. Its numerous architectural and structural awards confirm its technical success. Yet, the true measure of this case study’s success is its human element.

The complex, integrated parametric design process forced a level of collaboration and coordination previously unheard of in large-scale stadium projects, streamlining communication and enabling the architects and engineers to speak a common digital language. The final structure is a work of elegant compromise a large-scale public building that respects its small-scale neighbors, a futuristic glass bowl that is profoundly rooted in the history of its site. It is a powerful example of how digital tools can empower the human desire to build a structure that is both technically brilliant and emotionally resonant, a shining “crystal bowl” for Dublin’s skyline that truly draws people together.

FAQ’s:-

1. Why is the shape of the Aviva Stadium so unique and asymmetrical?

A. The unique, curvilinear shape is a direct response to the tight and complex urban site constraints. The stadium is intentionally low on the North side (with only a single seating tier) to reduce its visual impact and minimize shadowing on the residential homes located there, while maximizing height and seating capacity on the other sides.

2. What major engineering innovation was used to design the Aviva Stadium?

A. The most significant innovation was the extensive use of parametric modeling software from start to finish. This allowed architects and engineers to share a single, rule-based 3D model (a key component of BIM) that could instantly adjust the structure and form in response to design changes, ensuring coordination of the incredibly complex roof and façade geometry.

3. What is the “horseshoe truss” in the Aviva Stadium roof structure?

A. The horseshoe truss is the innovative, primary steel structure that supports the weight of the roof over the East, South, and West stands. Its name comes from its shape, which spans around the seating bowl but is open and lower on the North side, where it connects to the ground and is supported by large, tapering concrete super-columns.

4. How is the Aviva Stadium a sustainable building?

A. The stadium incorporated multiple sustainable features. These include the reuse of crushed concrete from the old stadium, the use of low-carbon concrete in its structure, and a large-scale rainwater harvesting system (storing 250,000 liters) that collects water from the roof for pitch irrigation.

5. What material gives the Aviva Stadium its distinctive transparent look?

A. The exterior skin, which wraps seamlessly around the roof and façade, is clad in approximately 19,000 square meters of translucent, shingled polycarbonate panels. This material allows daylight to flood the interior concourses and the pitch while creating a visually dynamic exterior that reflects the surrounding sky and light.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.