We have all heard the horror stories. A project starts with a promising vision and a healthy budget, but by the time the foundation is poured, change orders are piling up and the contingency fund is draining fast. It is a stressful reality for developers and architects alike. But what if the secret to avoiding this wasn’t just about cheaper materials or faster labor, but simply about timing?

The traditional workflow often brings structural engineers in after the architectural vision is set in stone. However, shifting this timeline and integrating structural expertise during the concept phase is a proven strategy to slash Construction Costs. By identifying efficiencies before a single drawing is finalized, project stakeholders can unlock savings of up to 15% a margin that often defines the success or failure of a venture.

The Hidden Impact of Late Integration on Construction Costs:-

When structural engineers are treated as a post-design necessity rather than creative partners, opportunities for optimization are lost. Imagine an architect designing a stunning cantilever that, unbeknownst to them, requires massive, custom-fabricated steel beams to support. If an engineer sees this weeks later, the design is already “locked,” and the expensive solution becomes the only solution.

This is where the budget bleeds. Late engagement leads to reactive engineering fixing problems rather than preventing them. By contrast, a collaborative approach ensures that structural realities inform the design, not just support it.

Read more on:- Why collaboration between contractors and structural engineers is key to successful projects

How Early Design Optimization Lowers Construction Costs:-

Value engineering shouldn’t be a painful process of cutting corners at the end of a project. It should be a proactive step at the beginning. When structural consultants are present at the table from day one, they can suggest subtle adjustments to column grids or load paths that are invisible to the end-user but massive for the bottom line.

For instance, aligning a structural grid with standard formwork sizes can dramatically reduce labor hours and waste. These “smart” decisions don’t compromise the aesthetic; they simply make the building more buildable. It is about understanding the role of the engineer not just as a calculator of loads, but as a designer of efficiency.

Read more on:- What is the role of a structural engineer

Reducing Material Waste to Cut Construction Costs:-

One of the largest line items in any project budget is raw materials. Over-designing is a common symptom of rushed engineering. When timelines are tight because the structural team was brought in late, engineers often resort to conservative, heavy assumptions to ensure safety without the luxury of time to refine the calculations.

Early involvement allows for iterative analysis. Engineers can optimize beam sizes, reduce concrete volumes, and select materials that offer the best balance of strength and price. Furthermore, selecting the right materials early on whether it is steel, concrete, or timber can prevent costly procurement delays later.

Mitigating Risks and Delays to Control Construction Costs:-

Time is money. Every day a project sits idle waiting for an RFI (Request for Information) response or a redesign is a day of lost revenue. A significant portion of these delays stems from clashes between architectural intent and structural feasibility.

Bringing the structural team in early helps identify these clashes when they are just lines on a screen, not physical conflicts on a job site. This is particularly effective when utilizing modern workflows. For example, moving from CAD to advanced modeling ensures that everyone is looking at the same 3D reality, allowing for “virtual construction” that highlights risks before ground is broken.

Read more on:- From Cad to BIM navigating the transition for enhanced project delivery

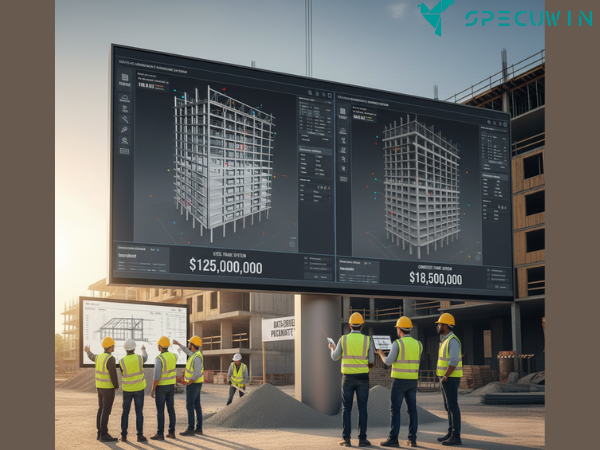

The Role of Technology in Estimating Construction Costs:-

The modern engineer brings more than just a calculator to the meeting; they bring powerful simulation tools. Technology allows for rapid prototyping of different structural systems. The team can quickly compare a steel frame versus a concrete frame in real-time to see which yields the better financial outcome.

This data-driven approach removes the guesswork. Instead of relying on rules of thumb, the project budget is based on accurate, analyzed quantities. This precision is vital for high-stakes projects, such as high-rise buildings, where a 1% variance can equal millions of dollars.

Conclusion: A Strategic Investment:-

Saving 15% on a project isn’t magic; it is management. It requires a shift in mindset to view structural engineering not as a commodity to be purchased as late as possible, but as a strategic asset to be leveraged immediately. If you are looking to secure your budget and ensure a smoother build, the first step is simple: hire the right team, and do it early.

FAQ’s:-

1. At what specific stage should I hire a structural engineer to save on expenses?

A. Ideally, you should engage a structural engineer during the Schematic Design or even the Pre-Design phase. Bringing them in before the floor plans are finalized allows them to suggest efficient grid layouts and structural systems that can define the project’s budget efficiency from the start.

2. How does early engineering involvement actually reduce the budget?

A. It reduces the budget primarily through material optimization and risk mitigation. Engineers can design lighter, more efficient structures if given time to analyze options. They also prevent expensive late-stage changes by identifying conflicts between the architecture and the structure before construction begins.

3. Will hiring an engineer earlier increase my upfront fees?

A. While you may pay for engineering hours earlier in the timeline, the total engineering fee often remains similar. More importantly, the savings generated from a more efficient design and fewer construction delays typically outweigh the early engineering fees by a significant margin (often 10x or more).

4. Can early structural input help with sustainability?

A. Yes. Efficient structural design uses less material (less concrete and steel), which lowers the project’s embodied carbon. Engineers can also suggest sustainable materials or construction methods that might be cheaper and greener, aligning with modern eco-friendly standards.

5. What happens if I wait until the construction documents phase to bring an engineer in?

A. Waiting this long forces the engineer into a “reactive” mode. They must design a structure to fit a fixed architectural shape, which often results in heavy, complex, and expensive structural solutions. It also increases the likelihood of RFI delays and change orders during construction.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.