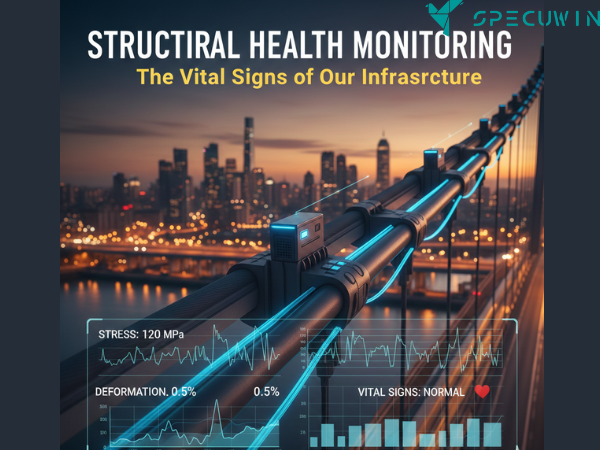

Imagine if a bridge could tell you it was feeling “tired” after a heavy storm, or if a skyscraper could alert you that a specific beam was carrying too much weight. For centuries, we have relied on visual inspections essentially looking at a structure to guess its condition. But today, the industry is shifting toward a more proactive approach: Health Monitoring.

Just as a doctor uses a heart rate monitor to track a patient’s vitals in real-time, modern engineering now allows us to track the pulse of our built environment. This isn’t just about avoiding collapse; it is about extending the life of our assets and making our cities smarter. In this guide, we will explore the technology, the benefits, and the future of Health Monitoring.

What is Structural Health Monitoring?:-

At its core, this concept is the implementation of a damage detection and characterization strategy for engineering structures. It involves the observation of a system over time using periodically sampled dynamic response measurements from an array of sensors.

In simpler terms? It is a nervous system for buildings.

Traditionally, we rely on scheduled check-ups. An engineer visits a site, looks for cracks, and perhaps runs a few tests. While this is necessary, it leaves gaps. A lot can happen between inspections. The automated systems used today fill those gaps, providing 24/7 surveillance. This shift is critical because it moves us from “reactive” maintenance (fixing things after they break) to “predictive” maintenance (fixing things before they break).

The Core Components of a Health Monitoring System:-

To understand how this works, we have to look at the anatomy of the setup. It isn’t just one machine; it is a network of technologies working in harmony.

1. The Sensory Network:-

These are the “nerves.” Engineers install various sensors depending on what needs tracking. Accelerometers measure vibration (crucial for wind or seismic activity), strain gauges measure stress on specific materials, and inclinometers measure tilt.

2. Data Acquisition:-

This is the “spinal cord.” The sensors collect massive amounts of raw data, which needs to be gathered and transmitted. In the past, this required miles of cabling. Today, wireless IoT (Internet of Things) devices transmit this data to the cloud instantly.

3. Data Processing and Diagnostics:-

This is the “brain.” Raw data is just noise until it is analyzed. Advanced algorithms process the information to identify patterns. If a bridge vibrates at a frequency that is slightly “off” compared to its baseline, the system flags it. This relies heavily on The role of technology in structural analysis and design, utilizing software that can interpret complex datasets instantly.”

Why We Need Health Monitoring for Aging Infrastructure:-

The world is filled with infrastructure built 50, 60, or even 100 years ago. Concrete degrades, steel corrodes, and soil conditions shift. Retrofitting these structures with sensors is often more cost-effective than rebuilding them entirely.

By utilizing these systems, asset owners can make informed decisions. Instead of replacing a roof because it is “old,” they can replace it because the data shows the load-bearing capacity has actually dropped. It optimizes budgets and ensures that money is spent where safety is actually at risk.

Furthermore, in seismic zones, these systems are invaluable. After an earthquake, it can take weeks for engineers to manually inspect every building in a city. A sensor-equipped building can instantly report whether its structural integrity remained within safe limits during the tremors. This capability is the next frontier in Innovations in earthquake-resistant design, allowing for immediate rapid assessment post-disaster.

The Role of Digital Twins in Health Monitoring:-

One of the most exciting developments in this field is the integration with Digital Twins. A Digital Twin is a virtual replica of a physical asset.

When you combine SHM data with a Digital Twin, you get a living, breathing virtual model. If a sensor on the physical building detects a temperature spike in a column, that column turns red on the 3D model on the facility manager’s screen. This visualization makes complex engineering data accessible to building owners who might not be structural engineers. This synergy demonstrates The revolutionary impact of digital twins on facility management and operations, turning static BIM models into dynamic dashboards.”

Future Trends in Health Monitoring

As we look forward, the technology is becoming less intrusive and more intelligent. We are seeing the rise of “smart materials” concrete that can sense its own cracks and even heal them reducing the need for external sensors entirely.

AI and Machine Learning are also playing a larger role. Eventually, the systems won’t just tell us that a beam is damaged; they will predict when it will fail with high accuracy, allowing for repairs to be scheduled years in advance. This is the ultimate goal: a built environment that is self-aware and self-reporting. These advancements are central to The future of structural engineering trends and innovations, pushing the boundaries of what is possible in construction.”

Conclusion:-

The transition from manual inspection to automated surveillance represents a paradigm shift in how we manage the built world. It saves money, it saves time, but most importantly, it saves lives. By listening to the structures we inhabit, we ensure they remain safe and functional for generations to come. The era of the “dumb” building is over; the era of Health Monitoring is just beginning.

FAQ’s:-

1. Is Structural Health Monitoring expensive to install?

A. While there is an upfront cost for sensors and software, it typically saves money in the long run. By detecting problems early, you avoid catastrophic failures and expensive emergency repairs. It also extends the lifespan of the structure, delaying the need for costly replacement.

2. Can this system be installed on old buildings, or is it only for new ones?

A. It is excellent for both. While it’s easier to integrate sensors during construction, “retrofitting” existing structures is very common. It is particularly useful for historical buildings or aging bridges where the structural integrity is uncertain.

3. Does SHM replace human structural engineers?

A. No. The system provides data, but it does not make decisions. A qualified structural engineer is still required to interpret the data, diagnose the root cause of the issues, and design the necessary repairs. The technology is a tool that makes the engineer’s job more accurate.

4. How does SHM differ from Non-Destructive Testing (NDT)?

A. NDT (like ultrasonic testing or X-rays) is usually a one-time “snapshot” performed during an inspection. SHM is continuous “video.” It monitors the structure 24/7/365, catching issues that might occur between scheduled NDT inspections.

5. What happens if a sensor fails?

A. Modern systems are designed with redundancy. If one sensor fails, others in the network usually cover the gap until the faulty unit can be replaced. Advanced systems can even detect when a sensor is giving false data and alert the maintenance team to check the device itself.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.