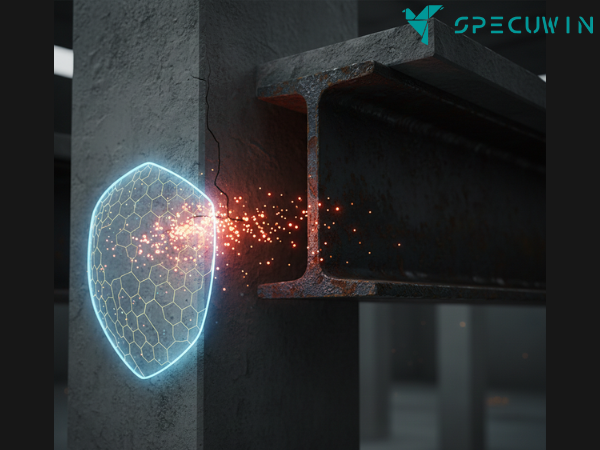

We often think of buildings as permanent fixtures unmovable giants made of stone, steel, and concrete that will outlast us all. But there is a quiet, persistent force that works tirelessly to undo that permanence. It doesn’t arrive with the bang of an earthquake or the roar of a storm; it creeps in slowly, hiding in the microscopic chemical reactions deep within your walls and beams. This force is Structural Corrosion.

Corrosion is the cancer of the construction world. It is the degradation of materials due to a reaction with their environment, and while we often dismiss a bit of rust on a gate hinge as a nuisance, the implications for load-bearing elements are far more severe. Whether you manage a commercial high-rise or are looking to protect a residential investment, understanding the mechanics of decay is vital.

In this guide, we will strip away the complex chemistry and focus on the practical realities of steel and concrete degradation. We will explore how to spot the early warning signs, the preventative measures you can take, and how to safeguard the longevity of your assets.

What Causes Structural Corrosion?:-

To fight the enemy, you must first understand it. At its core, Structural Corrosion is a return to nature. Refined metals like steel are in a high-energy state; they naturally want to revert to their lower-energy, more stable oxide forms (like iron ore).

In the context of the Architecture, Engineering, and Construction (AEC) industry, this usually manifests in two primary ways:

- Electrochemical Oxidation (Rusting): This occurs when steel is exposed to oxygen and moisture. The metal acts as an anode, losing electrons and deteriorating.

- Galvanic Corrosion: When two dissimilar metals are in contact in the presence of an electrolyte (like saltwater), one corrodes faster than the other.

However, the materials we use play a massive role in how fast this happens. Using the wrong concrete mix or steel grade for a specific environment is a recipe for disaster. You can learn more about how material choices define building safety in our post on The Impact of Material Selection on Structural Integrity.

Identifying Structural Corrosion in Steel Elements:-

Steel is the backbone of modern infrastructure. From the skeletal frames of skyscrapers to the intricate connections in bridges, its tensile strength is unmatched. However, it is uniquely vulnerable to the elements.

Detecting Structural Corrosion in exposed steel is often straightforward, but “hidden” steel requires a keener eye.

Visual Indicators:

- Surface Discoloration: The classic orange-brown or reddish hues are the first sign that the protective layer (paint or galvanization) has failed.

- Pitting: This is dangerous because it is localized. Small, deep holes form on the surface, significantly reducing the cross-sectional area of the beam without looking “ruined” from a distance.

- Pack Rust: This occurs between two steel plates or connections. As rust forms, it expands, physically pushing the plates apart and straining the bolts or rivets.

If you notice these signs, it is rarely a cosmetic issue it is a signal that the load-bearing capacity of that member is being compromised. This is one of the primary reasons building owners schedule routine assessments. If you aren’t sure what to look for, check our guide on Top 5 Signs Your Building Needs a Structural Inspection.

Spotting Structural Corrosion Within Reinforced Concrete:-

Concrete seems impervious, but it is actually a hard sponge. It is porous, allowing moisture, chlorides (salts), and carbon dioxide to seep in over time. Inside that concrete lies steel reinforcement bars (rebar). When that hidden steel corrodes, it creates a unique and destructive chain reaction.

Rust occupies a greater volume than the steel it replaces up to six times the volume. As the rebar rusts, it expands, exerting immense internal pressure on the surrounding concrete.

The Warning Signs:

- Spalling: This is when chunks of concrete crack and fall off, exposing the rusted rebar beneath.

- Rust Staining: Brown streaks “bleeding” out of cracks in the concrete indicate that the rebar inside is actively corroding.

- Delamination: This is a hollow sound when you tap the concrete surface (often on bridge decks or balconies), indicating the concrete has separated from the steel layers beneath.

This type of degradation is particularly common in older properties where waterproofing standards were different or maintenance has slipped. For those managing aging properties, this is a frequent topic in our discussion on Common Structural Problems in Old Houses and How to Fix Them.

Proactive Measures to Combat Structural Corrosion:-

The most cost-effective way to deal with corrosion is to prevent it before it starts. While you cannot change the laws of physics, you can delay them significantly through smart engineering and construction practices.

1. Barrier Protection:

This involves isolating the structural elements from the environment.

- Paints and Epoxies: High-performance coatings for steel.

- Concrete Cover: Ensuring there is enough depth of concrete covering the rebar to slow down the ingress of chlorides and carbonation.

2. Material Innovation:

We are moving beyond standard carbon steel. Modern engineering often utilizes materials that are naturally resistant to Structural Corrosion.

- Galvanized or Stainless Steel Rebar: While more expensive upfront, these drastically reduce lifecycle costs in harsh environments (like coastal areas).

- FRP (Fiber Reinforced Polymer): A non-metallic alternative that simply cannot rust. We dive deeper into these alternatives in our article on Modern Materials in Structural Engineering: Beyond Concrete and Steel.

3. Cathodic Protection:

This is a technique often used in pipelines and bridges. It involves connecting a “sacrificial anode” (a piece of metal like zinc that is more reactive than steel) to the structure. The corrosion eats the zinc instead of your structural steel.

Long-term Management of Structural Corrosion:-

Even with the best materials, time is the ultimate adversary. Building maintenance is not just about cleaning windows; it’s about managing the structural health of the facility.

Regular inspections are non-negotiable. A structural engineer will look for the subtle signs we discussed hairline cracks, water pooling, and joint failures. When you receive their findings, understanding the technical data is crucial for making budget decisions. If you find technical jargon confusing, review our resource on How to Read a Structural Engineering Report: Key Insights for Clients

Furthermore, in an era where sustainability is paramount, preventing corrosion is an act of environmental stewardship. Extending the life of a building reduces the carbon footprint associated with demolition and reconstruction. Learn how longevity links to green building in Sustainable Structures: Eco-Friendly Approaches in Modern Construction.

Conclusion:-

Structural Corrosion is inevitable, but structural failure is not. By understanding the chemical relationship between your building and its environment, and by implementing rigorous detection and prevention strategies, you can ensure your property remains safe and sound for generations. Don’t wait for the rust to show; the best time to act was yesterday, but the second-best time is today.

FAQ’s:-

1. Can Structural Corrosion be fixed, or does the element need to be replaced?

A. It depends on the severity. If detected early (surface rust or minor pitting), the steel can often be cleaned and recoated, or the concrete patched. However, if the cross-sectional area of the steel has been significantly reduced, reinforcement or total replacement may be necessary to ensure safety.

2. How often should I inspect my building for corrosion?

A. For commercial buildings or those in aggressive environments (like coastal areas or industrial zones), a visual inspection should happen annually, with a detailed structural audit every 3 to 5 years. Residential properties should be checked if cracks or stains appear.

3. Is stainless steel immune to Structural Corrosion?

A. No metal is 100% immune, but stainless steel is highly resistant. It can still corrode in low-oxygen environments or high-chloride environments (like swimming pools) if the wrong grade is used, but it far outperforms standard carbon steel.

4. Why is concrete spalling considered a safety hazard?

A. Spalling is dangerous for two reasons: First, the falling concrete can injure people below (especially from balconies or facades). Second, it exposes the load-bearing steel to the open air, accelerating the corrosion process and rapidly weakening the structure.

5. Does waterproofing prevent corrosion?

A. Yes, waterproofing is one of the best defenses. Since water is the electrolyte needed for the corrosion reaction to occur, keeping your structural elements dry through proper drainage, sealants, and membranes effectively pauses the corrosion process.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.