Have you ever wondered why a spider web doesn’t completely fall apart just because one strand breaks? The web adapts, redistributes the tension, and holds its shape. In the world of construction, we strive for that same resilience. While we often talk about beauty or raw strength, the true safety of a building relies on a principle called Robustness. It is the hidden safeguard that ensures a small accident doesn’t turn into a catastrophic tragedy.

In this guide, we will explore how engineers design structures to withstand localized failure, ensuring that if one component fails, the rest of the building stands strong.

What Exactly is Robustness in Structural Engineering?:-

At its core, this concept isn’t just about making things “strong.” A concrete block is strong, but if you crack it, it might shatter. Instead, this design philosophy focuses on “insensitivity to local failure.” It is the ability of a structure to withstand events like explosions, impact, or human error without being damaged to an extent disproportionate to the original cause.

Think of it like a team of people carrying a heavy log. If one person slips, the others must be able to shoulder the extra weight temporarily so the log doesn’t crush anyone. If the team lacks this quality, one person slipping causes the whole line to collapse. In engineering terms, we achieve this through redundancy and ductility ensuring there are alternative paths for gravity and forces to travel if a main column or beam is compromised.

For those just starting to explore this field, understanding the basics is crucial. You can learn more about the foundational principles in our guide on What is structural engineering.

Achieving Robustness Through Material Selection:-

The materials we choose play a massive role in whether a building will bend or break. To prevent a domino-effect collapse, engineers need materials that can deform (stretch or bend) under stress rather than snapping suddenly. This property is known as ductility. Steel is a classic example of a ductile material, whereas unreinforced concrete is brittle.

However, the industry is evolving. We are no longer limited to just standard choices. New innovations are allowing us to build lighter, stronger, and more resilient frames that contribute significantly to a building’s overall integrity. You can read deeper into these advancements in our article on Modern materials in structural engineering beyond concrete and steel.

The Critical Need for Robustness in High-Rise Structures:-

Nowhere is this concept more vital than in skyscrapers. When you build vertically, the stakes are incredibly high. A localized failure on the 10th floor of a 50-story building cannot be allowed to bring down the 40 floors above it. This phenomenon, often called “progressive collapse,” is the nightmare scenario engineers work tirelessly to prevent.

To combat this, tall buildings utilize complex systems of outriggers, belt trusses, and moment frames that tie the building together. These elements ensure that loads can be re-routed instantly if a critical support is lost. It is a complex puzzle of physics and geometry.

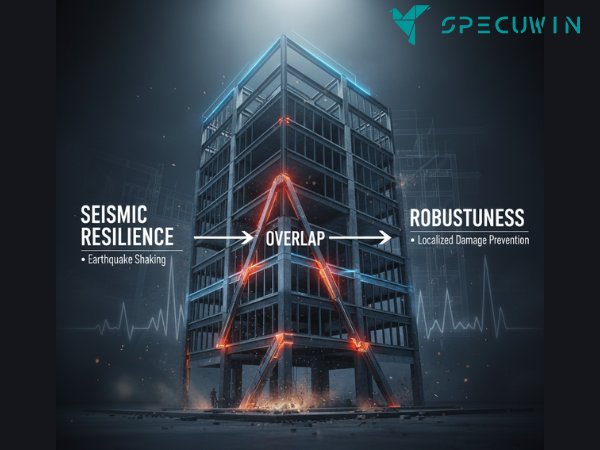

How Robustness Overlaps with Seismic Resilience:-

It is impossible to discuss preventing collapse without talking about earthquakes. While seismic design and disproportionate collapse prevention are distinct disciplines, they share a common goal: survival under extreme stress. A building designed to survive the violent shaking of an earthquake naturally possesses a high degree of continuity and tie forces features that also enhance its ability to survive other types of localized damage.

Seismic retrofitting often involves adding steel braces or strengthening joints, which inadvertently adds the redundancy needed for general structural resilience. If you are interested in how we protect buildings from ground motion, you might find our post on Innovations in earthquake resistant design very protecting.

Future Trends: Enhancing Robustness with Technology:-

As we move forward, the way we calculate and verify safety is changing. We are moving away from simple checklists and toward advanced computer simulations that can predict exactly how a building will react if a column is removed.

Digital tools allow us to “test” a building until it breaks in a virtual environment, long before the first brick is laid. This predictive capability is becoming a standard part of the workflow. To see where the industry is heading and how tech is shaping safety, explore our thoughts on The future of structural engineering trends and innovations.

Conclusion:-

Designing for the unexpected is the hallmark of great engineering. By prioritizing Robustness, we ensure that our built environment is forgiving, resilient, and safe. It is not just about keeping the roof up; it is about ensuring that even when things go wrong, the structure gives us the time and stability we need to stay safe.

FAQ’s:-

1. What is the difference between strength and robustness?

A. Strength refers to how much load a material or member can carry before breaking. Robustness refers to the ability of the entire system to survive the loss of a member without causing a total collapse. A structure can be very strong but not robust (i.e., brittle).

2. Is robustness required by building codes?

A. Yes, most modern building codes (like the Eurocodes and IBC) have specific requirements for structural integrity to prevent disproportionate collapse, especially for taller or high-occupancy buildings.

3. Can existing buildings be retrofitted for robustness?

A. Absolutely. Engineers can add steel bracing, carbon fiber wraps, or additional support columns to existing structures to improve their redundancy and tie forces, making them safer against localized failures.

4. What is “Progressive Collapse”?

A. Progressive collapse occurs when the failure of a primary structural element (like a column) leads to the failure of adjoining members, which in turn causes further failures, resulting in a collapse disproportionate to the initial damage.

5. How does a “Scan to BIM” workflow help with robustness?

A. Scan to BIM allows engineers to create an accurate 3D model of an existing building. This helps identify weak points, lack of redundancy, or deterioration that might compromise the structure’s resilience, allowing for precise strengthening strategies.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.