Imagine a crucial bridge or a high-rise office tower that collapses without warning. While thankfully rare, the specter of catastrophic structural failure hangs over the entire Architecture, Engineering, and Construction (AEC) industry, driving a constant, expensive effort to ensure safety. For decades, the standard approach to maintaining our built environment was reactive or preventative. Teams performed costly, scheduled inspections often manually searching for visible cracks, corrosion, or fatigue. The old world of structural health monitoring is being rapidly replaced by a new era of proactive intelligence. The solution lies in the convergence of big data, the Internet of Things (IoT), and advanced algorithms, giving rise to AI in Predictive Maintenance.

The Mechanics of AI in Predictive Maintenance:-

The concept of structural health monitoring has existed for years, but it was often limited by the sheer volume of data and the slow process of human analysis. The rise of AI in Predictive Maintenance changes this entirely by providing a framework to turn raw data into actionable intelligence at an unprecedented speed.

Read more on:- The Role of Technology in Structural Analysis and Design

1 Data: The Fuel for AI

The entire system begins with data collection. A modern structure equipped for predictive maintenance is essentially a nervous system of connected sensors. These IoT devices are deployed to measure every critical aspect of a structure’s health:

- Vibration and Strain: Sensors measure minute movements and stress levels, identifying subtle shifts that could indicate foundational problems.

- Environmental Factors: Thermometers, hygrometers, and wind speed sensors provide context, showing how structural materials react to changes in weather and climate.

- Acoustic Emissions: Microphones can detect high-frequency sounds produced by growing cracks or internal material failure.

- Visual Data: High-resolution cameras and drones capture imagery that AI models process to detect surface deterioration, rust, or sealant failure.

Crucially, this data is integrated into existing Building Information Modeling (BIM) systems. The BIM model acts as the digital twin and spatial backbone, providing the AI with the exact context (material, age, design load) for every sensor reading. This integration allows AI to not just see what is happening, but where and why. This level of integration between design and monitoring is a vital step forward in structural analysis and design.

2. Machine Learning Models at Work

The raw sensor data is useless without a brain to process it. This is where Machine Learning (ML) models, the core of AI in predictive maintenance, come into play. These algorithms perform two primary, interlocking functions:

- Anomaly Detection: The ML model is first trained on years of historical data representing the structure’s “healthy” state. It learns the normal patterns of vibration, expansion, and contraction. Once deployed, the AI continuously monitors the incoming live feed. If a sensor reading deviates significantly from the established healthy baseline, the AI flags it as an anomaly.

- Remaining Useful Life (RUL) Prediction: This is the “predictive” part of the process. Using time-series analysis and regression algorithms, the AI can extrapolate the rate of deterioration. Based on the current rate of fatigue or corrosion, the model calculates the probability of a structural component failing within a specific future timeframe. For example, it can predict with a high degree of confidence that a particular bridge joint will exceed its stress tolerance in the next six to eight months.

3. The Continuous Feedback Loop

The process is not static. Every maintenance action taken based on an AI alert is recorded and fed back into the ML model. The AI learns from the outcome of the repair, continuously improving its predictive accuracy and refining its understanding of the structure’s behavior. This self-optimizing feedback loop ensures that the system becomes more efficient and reliable over time.

Key Benefits: Why the AEC Sector is Adopting AI in Predictive Maintenance:-

The shift from manual inspection to intelligent, data-driven monitoring isn’t merely an upgrade; it’s a fundamental change that delivers profound benefits across the lifecycle of any structure, leading to enhanced safety, reduced costs, and improved sustainability.

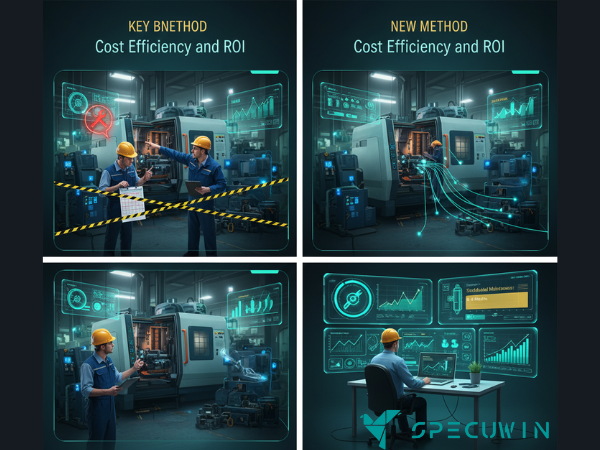

1. Cost Efficiency and Return on Investment (ROI)

The most tangible advantage of AI in Predictive Maintenance is its impact on the bottom line. Traditional preventative maintenance often involves unnecessary work inspecting or replacing components based on a calendar schedule, regardless of their actual condition. This leads to wasted labor, materials, and potential downtime.

AI eliminates this waste by adopting a condition-based strategy. By accurately forecasting a component’s Remaining Useful Life (RUL), maintenance teams only intervene when data indicates a high probability of imminent failure. This optimization leads to:

- Reduced Unexpected Downtime: Critical infrastructure, like manufacturing plants or data centers, can suffer catastrophic financial losses from unplanned outages.

- Optimized Labor: Instead of performing broad, time-consuming inspections, engineers can direct their expertise immediately to the flagged area, minimizing site time and labor costs.

- Maximized Component Lifespan: Components are allowed to run their full course without premature replacement, stretching asset value.

2. Enhanced Safety and Risk Mitigation

While cost savings are important, the primary driver for using AI in predictive maintenance is the dramatic improvement in public and operational safety. AI and IoT systems operate 24/7, providing a continuous, unbiased assessment that human inspectors cannot match.

The system’s ability to detect subtle, compounding stress before it is visible to the naked eye is a game-changer. It provides real-time alerts on critical failures, enabling immediate response and evacuation if necessary. This capability is paramount when tackling frequent and costly issues like the common structural issues that plague older buildings, such as foundation settlement or corrosion. By flagging these problems early, AI systems turn potential crises into manageable repairs, actively saving lives and preventing catastrophic economic damage.

3. Longevity and Sustainability

The final benefit aligns with modern demands for sustainable infrastructure. By keeping structures in optimal condition for longer, AI monitoring extends the overall service life of a building or bridge. This is a critical sustainability factor, as the construction and demolition of new structures are massive generators of CO2 emissions and waste. Furthermore, by ensuring materials are used efficiently and repairs are made optimally, AI helps minimize the carbon footprint associated with maintenance itself.

Read more on:- Top 10 Structural Issues in Residential Buildings

Real-World Applications and Case Studies:-

The technology of AI in Predictive Maintenance is moving rapidly out of the lab and into the real world, proving its immense value across complex and critical infrastructure types.

1. Bridges and Transportation Infrastructure

Bridges are constantly subject to heavy, dynamic loads and environmental stressors. Monitoring metal fatigue in steel tendons or micro-cracking in concrete under continuous traffic is virtually impossible for human teams. AI systems, deployed with dense networks of vibration and strain gauges, are perfect for this task. They can analyze the “signature” of a bridge’s movement, instantly identifying anomalies caused by overloaded trucks, seismic events, or material degradation. This has already led to successful interventions on major crossings, preventing potentially devastating failures.

2. High-Rise Buildings and Complex Structures

For monumental projects, such as the structural engineering of high-rise buildings, the complexity of monitoring thousands of connections, facade elements, and core structures is staggering. AI platforms integrate data from sensors measuring wind load, thermal expansion, and even the verticality of the structure. For example, in monitoring a skyscraper’s foundation, an AI system can process subtle data changes to flag settlement issues far sooner than traditional leveling surveys, giving engineers the maximum amount of time to deploy deep-pile remediation strategies.

3. Utilities and Manufacturing

Beyond the built environment, the technology is essential for industrial assets. AI is used to monitor the health of pipelines, wind turbines, and power transmission towers. In a wind farm, AI analyzes the acoustic profile of turbine gearboxes to predict bearing failure, shifting maintenance from reactive emergency repairs to planned, routine replacement, maximizing energy generation uptime. These systems are proving that the investment in smart monitoring pays for itself not through a single, dramatic catastrophe averted, but through the consistent, cumulative effect of optimized operations and maximized asset lifespan.

Challenges and the Future of AI in Predictive Maintenance:-

While the advantages of this technology are clear, its widespread adoption is not without hurdles. Understanding these challenges and the future outlook is crucial for any firm looking to invest in AI in Predictive Maintenance.

1. Current Challenges to Adoption

- Initial Cost and Integration: The upfront investment in installing hundreds or thousands of IoT sensors and the necessary data processing infrastructure can be substantial. Integrating this new digital layer into existing, often analog, infrastructure requires careful planning.

- Data Quality and Security: AI is only as good as the data it consumes. Poorly calibrated sensors or inconsistent data streams lead to inaccurate predictions (the “garbage in, garbage out” problem). Furthermore, a hyper-connected structure presents a new cybersecurity risk vulnerable access points that must be robustly defended.

- Regulatory Hesitation: Building codes and regulations are notoriously slow to adapt. Integrating AI-driven maintenance records into official sign-offs requires new legal and regulatory frameworks that many municipalities have not yet established.

2. The Road Ahead

The trajectory for AI in Predictive Maintenance is one of rapid integration and increasing sophistication. The future of structural engineering will be defined by the seamless blending of the physical and digital worlds. The next generation of this technology is already here in the form of Digital Twins. These are virtual, high-fidelity replicas of physical assets. An AI system can run endless “what-if” scenarios on the Digital Twin, simulating the impact of a severe hurricane or a specific material fatigue rate, without risking the actual structure.

Read more on:- The Future of Structural Engineering: Trends and Innovations

Conclusion:-

The traditional era of inspecting structures with a clipboard and binoculars is over. The rise of AI in Predictive Maintenance represents a non-negotiable step into the future of the built environment, driven by the need for greater efficiency and absolute safety. By leveraging data and machine intelligence, we are transforming our structures from passive recipients of decay into actively monitored, self-aware assets. This ensures that the buildings, bridges, and infrastructure we rely on will not just be durable, but truly future-ready.

FAQ’s:-

1. How is AI Predictive Maintenance different from traditional scheduled maintenance?

A. Traditional maintenance is time-based, relying on fixed schedules, while AI Predictive Maintenance uses real-time data from sensors to predict exactly when a structural component is likely to fail, allowing for action only when necessary.

2. What types of structures can benefit most from AI monitoring?

A. Structures under constant stress, such as bridges, dams, high-rise buildings, and aging critical infrastructure, benefit the most due to the high costs and risks associated with their failure.

3. Is AI replacing structural engineers in the maintenance process?

A. No, AI acts as a powerful tool. It replaces manual, repetitive data collection and analysis, allowing structural engineers to focus their expertise on interpreting the AI-generated insights and designing the best repair strategies.

4. What kind of data does AI use to predict structural failures?

A. AI analyzes data from IoT sensors, including strain, vibration, temperature, humidity, corrosion levels, and even visual data from drone inspections, comparing it against historical data and BIM models.

5. How long does it take to implement an AI Predictive Maintenance system on an existing structure?

A. The timeline varies significantly based on the structure’s size and age. It involves the installation of sensors, the establishment of a data collection network, and the training of the AI model, which can take several months to achieve reliable predictive accuracy.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.