We have all heard the saying, “You get what you pay for.” In the world of construction, this phrase often looms like a dark cloud over budget discussions. Clients and developers are constantly under pressure to reduce expenditures, yet the fear of creating an unsafe building is (rightfully) distinct and terrifying. Is it possible to shrink the budget without shrinking the safety margins? The answer is yes, but it requires a strategic shift in how we approach the building process.

Implementing cost-saving measures isn’t about buying cheaper cement or skipping necessary reinforcements. It is about optimizing the design, eliminating waste, and making smarter decisions before the first shovel even hits the ground. By focusing on efficiency rather than mere reduction, you can protect the “bones” of your building while still keeping your wallet happy. Below, we explore actionable strategies to achieve this balance.

1. Start with a Solid Foundation for Cost Saving:-

It might seem counterintuitive to spend money to save money, but nowhere is this truer than in the initial geotechnical investigation. Many project owners try to skimp on soil testing to save a few thousand upfront. This is a classic “penny wise, pound foolish” mistake.

If you don’t know exactly what lies beneath your site, your structural engineer has to make conservative assumptions. They will design a foundation capable of handling the worst-case scenario, which means more concrete and more steel than you might actually need. Conversely, if the soil is worse than expected, you face catastrophic costs during construction when you have to halt work to redesign the footing.

Accurate data allows engineers to design efficient, targeted foundations. For a deeper dive into why this step is non-negotiable, you should read about The importance of soil testing in structural engineering.

2. Smart Material Choices for Cost Saving Without Quality Loss:-

Materials often make up the bulk of the structural budget. However, “strongest” doesn’t always mean “best” for every application. Engineers often default to high-grade finishes or standard materials simply because that is what was used on the last job.

To drive cost saving in this area, you need to look at availability and application. For example, sourcing local materials drastically reduces transportation costs. Furthermore, using a slightly different grade of steel or concrete that is specifically optimized for your building’s load requirements rather than a blanket high-grade specification can shave significant percentages off the bill.

It is crucial to understand that swapping materials isn’t about using “weaker” stuff; it’s about matching the material performance to the actual demand of the structure. You can learn more about how these choices affect safety in our article on The impact of material selection on structural integrity.

3. Simplifying Design is the Ultimate Cost Saving Hack:-

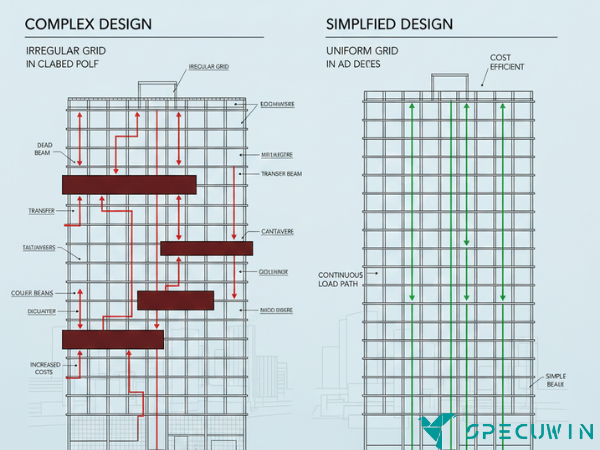

Architectural flair is wonderful, but structural complexity is expensive. When a design calls for transfer beams (where a column doesn’t go all the way to the ground but rests on a beam), deep cantilevers, or irregular grid spacing, the price of the structure skyrockets.

The most effective cost-saving strategy is often found in the geometry of the building. “Load path continuity” is the technical term, but it simply means stacking things on top of each other. When a column sits directly on top of the column below it, the load travels straight down to the foundation. This requires less steel reinforcement and simpler connections.

Standardizing the grid spacing also allows contractors to reuse formwork (the molds for concrete), which cuts down on labor and material waste. Simple doesn’t have to mean boring; it just means efficient.

4. Collaborative Teams Drive Cost Saving Initiatives:-

One of the biggest money pits in construction is the “Request for Information” (RFI) and the dreaded Change Order. These usually happen when the drawings don’t work in the real world, or when the contractor discovers something the engineer didn’t account for.

Traditionally, the architect designs, the engineer calculates, and the contractor builds—often in silos. Breaking down these walls is essential. When you bring the structural engineer and the contractor together early in the design phase, they can identify expensive constructability issues before they are baked into the design.

For instance, a contractor might suggest a different pouring schedule that requires a slight design tweak but saves weeks of labor. This synergy is vital. Read more about why Collaboration between contractors and structural engineers is key to successful projects.

Furthermore, ensuring you have the right expertise on board prevents costly errors from the start. If you are unsure how to vet your team, check out our guide on How to choose the right structural engineer for your project.

5. Leveraging BIM for Predictive Cost Saving:-

In the modern age, trying to build a complex structure without digital verification is a financial gamble. Building Information Modeling (BIM) allows us to build the project virtually before we build it physically.

BIM is a massive cost-saving tool because it detects “clashes.” Imagine realizing that a major structural beam runs right through where the HVAC ducting is supposed to go. If you find this on the construction site, you have to rip out work, delay the schedule, and pay for emergency redesigns. If you find it in a BIM model, you just click and drag the beam or the duct.

Beyond just avoiding errors, BIM helps in accurate quantity take-offs, meaning you order exactly the amount of material you need, reducing waste. To understand how this technology is reshaping the industry, look at How BIM is transforming consultancy.

6. Standardization and PEBs as Cost Saving Tools:-

For commercial and industrial projects, custom fabrication is the enemy of the budget. Custom shapes require custom molds, custom transport, and specialized labor.

Pre-Engineered Buildings (PEBs) are a fantastic solution. These structures are designed and fabricated in a factory and shipped to the site for assembly. Because the components are standardized, the manufacturing costs are lower, and the erection time is significantly faster. Faster construction means lower labor costs and a quicker return on investment because the building can be occupied sooner.

If your project allows for it, moving away from traditional on-site fabrication to a PEB model can yield massive savings. You can explore this further in our post on The benefits of pre-engineered buildings for commercial projects.

Conclusion:-

Saving money on a construction project should never mean losing sleep over the building’s stability. By investing in soil testing, optimizing material choices, simplifying the structural grid, fostering collaboration, using BIM, and considering pre-engineered options, you can significantly reduce costs. The goal of cost saving is not to build “cheap” it is to build “smart.”

FAQ’s:-

1. Can I switch materials during construction to save money?

A. Yes, but only with the approval of the structural engineer. Switching from steel to concrete or changing the grade of materials affects the load-bearing capacity. It must be recalculated to ensure safety is not compromised.

2. Does hiring a more expensive structural engineer actually save money?

A. Often, yes. A highly skilled engineer can optimize a design to use less material while maintaining strength. A cheaper, less experienced engineer might “over-design” the structure to be safe, costing you much more in materials than you saved on their fee.

3. What is the most expensive structural mistake to avoid?

A. Changing the design after construction has started. “Change orders” are the leading cause of budget overruns. Investing in detailed planning and BIM modeling upfront mitigates this risk.

4. How does soil testing reduce construction costs?

A. Without accurate soil data, engineers must assume the soil is poor and design an expensive, heavy-duty foundation. If the testing reveals the soil is actually good, you can use a lighter, cheaper foundation design.

5. Is a rectangular building always cheaper than a curved one?

A. Generally, yes. Rectangular buildings use standard formwork and have simple load paths. Curves and irregular shapes require custom fabrication and more complex labor, which drives up cost saving challenges.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.