There is a comforting logic to the idea that “more is better.” If a little bit of reinforcement keeps a building standing, surely doubling it makes the edifice invincible, right? This is the most pervasive Structural myth in the construction industry today. Clients often assume that packing a design with heavy steel sections guarantees safety, but the reality of engineering is far more nuanced. In fact, blindly increasing the amount of metal can lead to dangerous failure modes, inflated costs, and environmental irresponsibility.

In this post, we will dissect why balance, not bulk, is the true measure of Structural integrity. We will explore how modern engineering prioritizes smart distribution over raw mass and why the “more steel” mentality is a relic of the past.

The Dangers of Structural Over-Reinforcement:-

When we talk about designing a safe framework, the goal is not just strength; it is “ductility.” Ductility is the ability of a material to deform under stress (like an elastic band stretching) before it snaps.

If you pack a concrete beam with too much rebar, you create a condition known as being “over-reinforced.” In this scenario, the steel is so strong that it won’t yield even when the load becomes critical. Instead, the concrete which is brittle crushes suddenly and explosively without warning. A properly designed beam allows the steel to stretch first, causing visible sagging and cracking. This gives occupants a warning to evacuate. By simply adding more metal, you might actually remove the building’s ability to “warn” its users of impending failure.

Furthermore, heavier elements add “dead load” the weight of the building itself. If the framework is too heavy, the foundation must work harder to hold it up. This can lead to settlement issues or require massive, expensive foundation systems that were otherwise unnecessary.

The Importance of Material Selection in Structural Systems:-

Strength is not solely defined by quantity; it is defined by the quality and appropriateness of the materials used. A common mistake is treating all steel as if it performs the exact same function regardless of where it is placed. However, the interaction between different elements concrete, composites, and metal determines the overall stability of the edifice.

Choosing the right grade and type of material is far more critical than simply increasing the volume. For example, using high-strength alloys in specific zones often yields better results than using generic mild steel everywhere. Engineers must evaluate how these materials interact to resist forces like wind, gravity, and seismic activity.

Recommended Reading: To understand more about choosing the right components for your project, check out our guide on The Impact of Material Selection on Structural Integrity.

Technology’s Role in Structural Analysis and Optimization:-

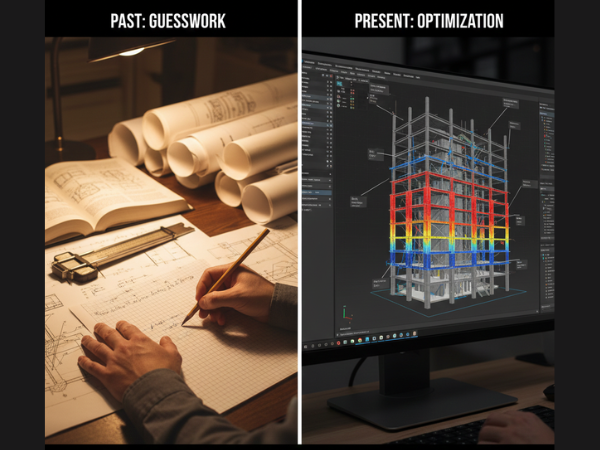

In the past, engineers often used “rules of thumb” or simplified calculations, leading to conservative designs with excess material just to be safe. Today, we have moved past the era of guesswork. We now utilize advanced Building Information Modeling (BIM) and sophisticated analysis software to simulate exactly how forces travel through a building.

These digital tools allow design professionals to “shave” the design, placing reinforcement only where it is strictly needed. This process, known as optimization, ensures that every ounce of steel is performing a specific job. It transforms a clunky, heavy skeleton into a lean, efficient athlete. By visualizing stress points digitally, we can reduce waste significantly while actually increasing the safety factor.

Recommended Reading: Curious about the software driving these decisions? Read about The Role of Technology in Structural Analysis and Design.

Why Structural Sustainability Depends on Efficiency:-

The construction industry is one of the largest contributors to global carbon emissions, and the production of steel is energy-intensive. Every extra ton of metal used in a project represents a significant amount of embodied carbon.

The “more is better” mentality is essentially an environmental liability. A truly robust design is one that achieves maximum stability with minimum resource consumption. Modern green building standards reward efficiency. By reducing the weight of the framework, we reduce the carbon footprint of the entire development. This approach doesn’t just save money on raw materials; it aligns the project with global sustainability goals and certifications like LEED or BREEAM.

Recommended Reading: Learn how efficiency contributes to a greener future in our article on Sustainable Structures: Eco-Friendly Approaches in Modern Construction.

Modern Materials Changing the Structural Landscape:-

While steel has been the king of construction for over a century, relying on it exclusively or excessively is becoming outdated. We are seeing a rise in alternative materials that offer high strength-to-weight ratios without the bulk.

From cross-laminated timber (CLT) to fiber-reinforced polymers, these innovations allow us to build tall and strong without defaulting to heavy metal grids. These materials often behave differently under load, requiring a sophisticated understanding of physics rather than a brute-force approach. Integrating these modern alternatives can often solve problems that adding more rebar simply cannot.

Recommended Reading: Explore what else is out there in our deep dive into Modern Materials in Structural Engineering: Beyond Concrete and Steel.

Conclusion: The Structural Reality Check:-

The belief that “more steel equals stronger” is a dangerous oversimplification. It ignores the complex physics of how buildings behave, the risks of brittle failure, and the environmental cost of waste. True strength comes from intelligent design, precise analysis, and the balanced use of materials.

As we move toward a future of smarter, greener, and more efficient cities, we must abandon the brute-force methods of the past. If you are planning a project, look for an engineering team that values optimization over excess. Your building will be safer, lighter, and more sustainable for it.

FAQ’s:-

1. Does adding more rebar always prevent concrete from cracking?

A. No, not necessarily. While reinforcement helps control crack widths, adding too much can actually lead to congestion, preventing concrete from flowing properly during pouring. This causes voids and honeycombing, which weakens the element.

2. Can a building be too stiff?

A. Yes. In earthquake zones, a building needs to be flexible to absorb seismic energy. If you add too much steel and make the frame too rigid, it may not be able to sway, leading to catastrophic failure at the foundation or connections during a tremor.

3. How do engineers decide how much steel to use?

A. Designers use strict building codes and computer simulations to calculate the specific loads (gravity, wind, people, furniture). They apply a “factor of safety” to these calculations to determine the precise amount of reinforcement required, without going overboard.

4. Is steel the strongest building material available?

A. In terms of pure tensile strength, it is very high, but “strength” is relative. Carbon fiber, for example, has a higher strength-to-weight ratio. The “best” material depends on the specific application, cost, and environmental constraints of the project.

5. Why is “brittle failure” considered worse than “ductile failure”?

A. Ductile failure happens slowly the beam bends and cracks, giving people time to escape. Brittle failure is sudden and instant like a piece of chalk snapping. Engineers always design for ductility to save lives, even if the building itself is damaged.

Read More On:-

For more information about engineering, architecture, and the building & construction sector, go through the posts related to the same topic on the Specuwin Blog Page.

Find out more accurately what we are going to take off in the course of applying leading new technologies and urban design at Specuwin.